Today’s precision welding marketplace specializing in laser spot welding or laser seam welding applications,

have a wide range of new technologies available to enhance their ability to provide the highest level of

quality, craftsmanship, and service to their clients.

The FiberStar 8800 Series manual welding systems are ideal for a variety of common welding applications

including plastic injection mold, dies and tooling repair, complex electronic components, high-precision

industrial assemblies, pressure-sensitive hermetic laser sealing, and other unique industrial applications

for the automotive, aerospace, aviation, computer, medical device, mold repair, and consumer product

industries.

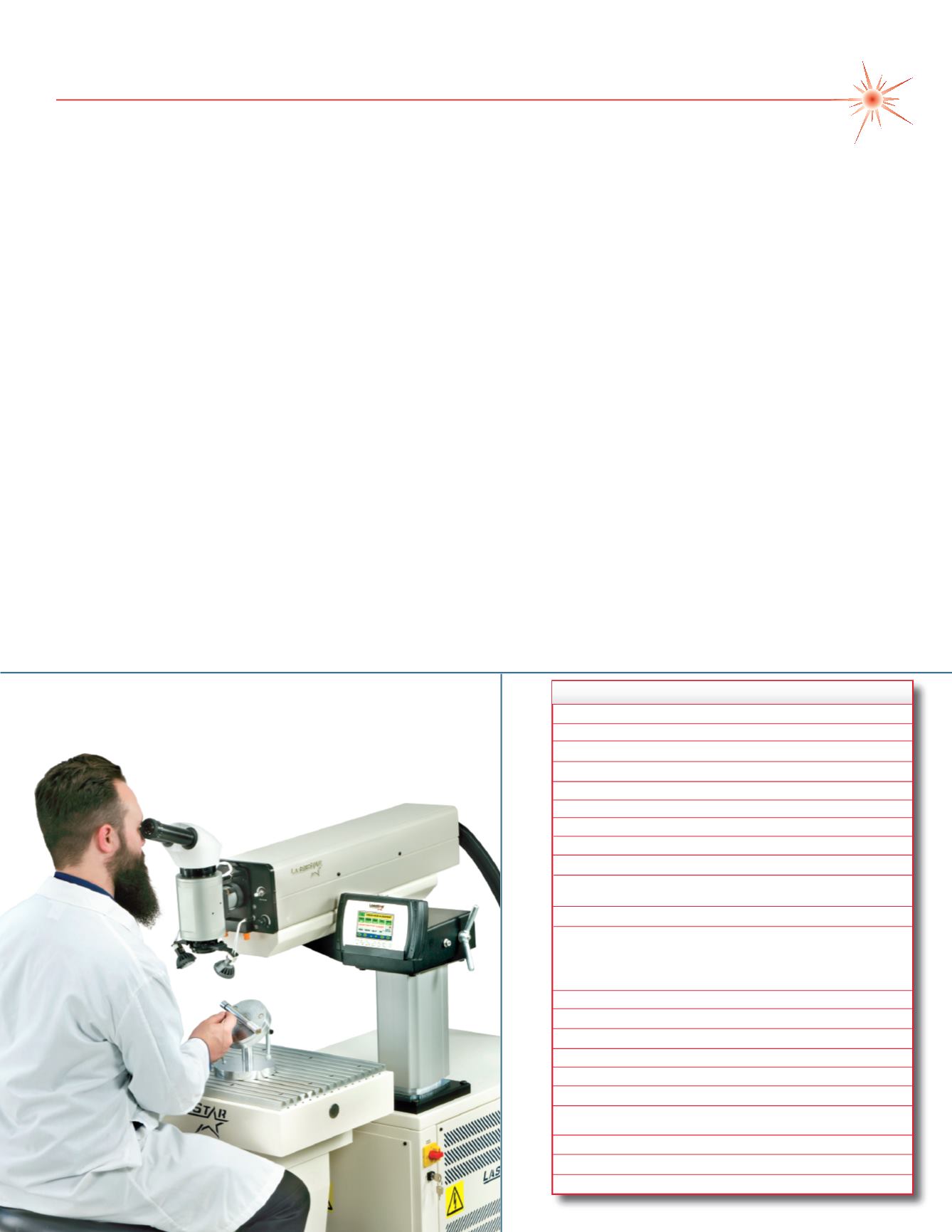

Operators hold parts in their hands while viewing the application through a stereo-microscope in the

welding zone. An internal cross-hair allows the operator to easily align and weld the parts at the correct

location.

FiberStar 8800 Series Systems offer state-of-the-art laser resonator technology which provides high peak

power, optimal performance & throughput, higher up time, enhanced electrical efficiency, and a space

saving air cooled design. Solid state diodes provide instantaneous power with no “warm up time” required.

The laser source is a permanently sealed design that protects against dust and dirt, does not require

adjustment, has no consumable parts, and requires no maintenance. These features help to ensure the

FiberStar systems performance resulting in stable, consistent material processing for years of operation.

Many materials can be laser welded including 300 and some 400 series stainless steel, mild steels, nickel

and nickel alloys, aluminum and aluminum alloys, titanium, precious metal alloys (gold, silver, and platinum),

etc.

FiberStar offers multiple power levels (150, 300, 450 Watts) to meet a wide variety of application

requirements.

8800 Series Open Workspace Welding Workstations

O

PEN

W

ORKSPACE

W

ELDING

W

ORKSTATION

8800 Series

44

LaserStar Lasing System

Class 4 / Fiber

Wavelength

1,070nm

Operating Mode

Pulse or Continuous

Output Power

150 Watt / 300 Watt / 450 Watt

Minimum Peak Power

1.5kW / 3.0 kW / 4.5 kW

M

2

2.0 - 15.0

Pulse Length

0.2 - 50 Milli-seconds

Pulse Frequency

0,5 - 20 Hz

Burst (Count) Mode

>25 Micron

Cooling System

Internal Forced Air /

Optional Chiller Ready

Cooling Capacity

24 Hour Continuous

Supply Circuit

120V (+/- 10%), 50/60 Hz

15 Amp, Single Phase

208V (+/- 5%) or 230V (+/- 10%)

50/60 Hz, 15 Amp, Single Phase

Binocular Microscope

15x (optional 25x, 40x)

Illumination System

LED Natural Lighting

Programming Memory

99 Text Cells

Parameter Adj. Features

External Touchscreen/O.I.T.

Motorized Beam Expander

Yes

Shield Gas Supply

Dual Nozzles

Dimensions

24”W x 48”L

609mm x 1150mm

Warranty Coverage

(Parts & Labor)

As Quoted

Laser Safety Certification

FDA(CDRH), UL, CSA, CE

Country of Origin

Made In USA

NOTE: Fatigue test data can be provided upon request.

8800 Series

Open Workspace

Fiber Welding Workstation

Shown with Magnetic Jig