O

PEN

W

ORK

S

PACE

F

IBER

W

ELDING

W

ORKSTATION

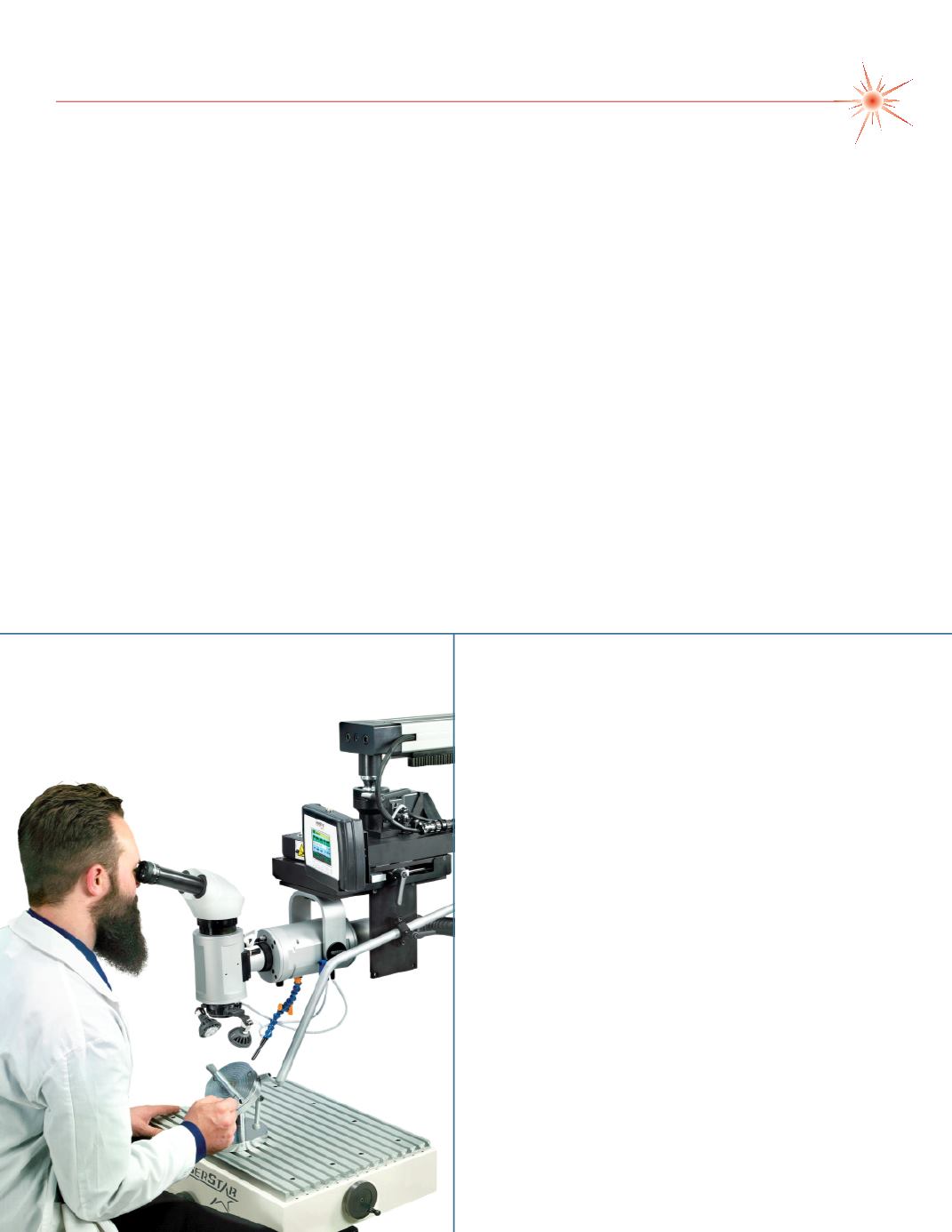

8700-2 Series with Universal Jig

Today’s mold repair micro-welding laser industry is characterized by rapidly changing, ever-evolving

customer demands and intense competition. Innovative ideas, successful designs and a strong

commitment to superior quality and performance are the fundamentals of LaserStar Technologies

Corporation.

FiberStar 8700-2 Series Fiber Laser Welding Workstations offer state-of-the-art laser resonator

technology which provides high peak power, optimal performance and throughput, higher up time,

enhanced electrical efficiency, and a space saving air cooled design. Solid state diodes provide

instantaneous power with no “warm up time” required.

The laser source is a permanently sealed design that protects against dust and dirt, does not require

adjustment, has no consumable parts, and requires no maintenance. These features help to ensure

the FiberStar systems performance resulting in stable, consistent material processing for years of

operation

.

Fiber laser welding technology produces a sharp, focused light beam that consistently melts a very

small area of metal. The benefit of the technology is that very little heat is generated at the weld

point allowing users to easily laser weld > 0.025mm from complex, heat sensitive, intricate parts

while providing unparalleled parameter flexibility from 0 – 100% duty cycle.

The Universal Jig Fiber Laser Welding Workstation offers a significant, competitive advantage for

today’s operators looking to unleash the power of hot light, benefit from a comfortable, ergonomic

design and ensure optimal platform flexibility for the widest range of on-site mold repair welding

applications.

42

FiberStar laser welding systems are ideal for a wide range

of large plastic injection mold, tool & die maintenance and

repair applications.

•

Lay a bead from .0025” / 0.40mm

•

Repair slots, pockets, radius contours and angles

•

Repair polished, textured and engraved surfaces

•

Repair thin walls with little or no warping

•

Repair parting line edges and heat sensitive areas

•

Alloys include tool steel, aluminum, copper,

titanium and powdered metals

The FiberStar produces a high quality result, reduces

the amount of handwork required before polishing and

practically eliminates sink lines.