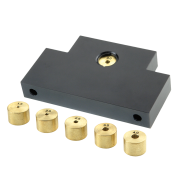

Aperture Kit (Manual Laser Welding Systems)

APERTURE KIT (6 SIZES) (SINGLE BRACKET ASSEMBLY WITH CONVERSION WRENCH) INSERT DIAMETERS: 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm Compatible with the Following Series: 992, 972, 1902, 1902-MFX, 7803, 7900, 7601, 7601-MFX, 8803, 8900

Blue Air Filter Kit (7700-150W / 8000)

The Blue Air Filter Kit 7700-150W / 8000 is designed to provide efficient air filtration for your laser welding system. This high-quality filter helps reduce dust buildup, ensuring consistent airflow and preventing contaminants from affecting machine performance. Whether for routine maintenance or replacement, the Blue Air Filter Kit 7700-150W / 8000 is essential for keeping your equipment running smoothly and efficiently.

Deionized Water (1 Gallon Jug)

Each Deionized Water 1-Gallon Jug is shipped separately to maintain the integrity of the container and prevent spillage, therefore the shopping cart will only allow you to order one (1) gallon per transaction. The listed price includes the cost of the deionized water but an additional fee of $19.50 for ground transportation is required. If you require an alternative shipping method, please do not place your order online. Instead, contact LaserStar directly at +1-407-248-1142 and ask for the inside sales desk to arrange your preferred transportation service.

Dionized Water Filter Cartridge (960/970/1000/1200/1900XL/2000/7000/7700/7800)

The Dionized Water Filter Cartridge 960 / 970 / 1000 / 1200 / 1900XL / 2000 / 7000 / 7700 / 7800 is designed to maintain pure water circulation in laser welding systems. This high-quality filter removes contaminants, preventing buildup and ensuring efficient cooling. Regular replacement of the Dionized Water Filter Cartridge 960 / 970 / 1000 / 1200 / 1900XL / 2000 / 7000 / 7700 / 7800 extends the lifespan of your equipment and keeps your laser system performing at its best.

Dionized Water Filter Cartridge (980/990)

The Dionized Water Filter Cartridge 980 / 990 is essential for maintaining clean and efficient water circulation in your laser system. This high-quality filter helps remove impurities, preventing buildup and ensuring optimal cooling performance. Regular replacement of the Dionized Water Filter Cartridge 980 / 990 extends the lifespan of your equipment, keeping your laser welder running at peak efficiency.

Distilled Water (1 Gallon Jug)

Each Distilled Water 1-Gallon Jug is shipped separately to maintain the integrity of the container and prevent spillage, therefore the shopping cart will only allow you to order one (1) gallon per transaction. The listed price includes the cost of the deionized water but an additional fee of $19.50 for ground transportation is required. If you require an alternative shipping method, please do not place your order online. Instead, contact LaserStar directly at +1-407-248-1142 and ask for the inside sales desk to arrange your preferred transportation service.

Distilled Water Filter Cartridge (993)

The Distilled Water Filter Cartridge 993 is essential for maintaining a clean and efficient water circulation system in laser welders. Designed to remove impurities, this high-quality filter helps prevent buildup, ensuring optimal cooling and performance. Regular replacement of the Distilled Water Filter Cartridge 993 extends equipment lifespan and keeps your laser system operating at peak efficiency.

Distilled Water Filter Catridged (972/1902)

The Distilled Water Filter Cartridge 972 / 1902 is designed to maintain pure water flow in laser welding systems. By effectively removing impurities, this high-quality filter helps prevent buildup and ensures efficient cooling performance. Regular replacement of the Distilled Water Filter Cartridge 972 / 1902 extends equipment lifespan and keeps your laser system running smoothly.

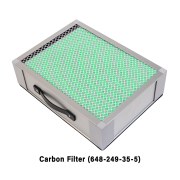

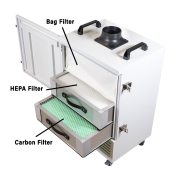

E350 LASERSTAR FUME EXTRACTOR w/Hose Kit

The E350 Fume Extractor Exhaust Unit is a powerful, heavy duty vacuum system designed for efficient removal of large, heavy particles. Engineered with a brushless high-speed turbine and 430 M³/h airflow, it delivers superior suction and filtration for continuous usage in demanding environments. The unit includes HEPA and odor filters, capturing 99.97% of fine particles while removing unwanted fumes.

Key Features of the Heavy Particle Vacuum Exhaust Unit:

Compact, Robust, Heavy Duty DesignTop Rated 430 M³/h for Powerful Suction

HEPA Filter Captures 99.97% of Fine Particles Odor Carbon Filter Effectively Removes Fumes Enhanced Noise Reduction Produces < 53dB Brushless High-Speed Turbine for Long-Lasting Performance

Interchangeable 2 Meter PVC Hose or Flexible Hard Plastic Hose for Versatile Use

Disposable Bag Filters Capture Particles & Precious Metals for Easy Refining

Two Models Available: 120V or 220V Supply Circuits One Year Limited Warranty

This Heavy Particle Vacuum Exhaust Unit is an excellent solution for welding, cutting, soldering, cleaning, marking & engraving applications requiring powerful and reliable filtration for large debris and fine particles.

Note: The listed price includes $155 prepaid UPS Ground Freight (990-F-249-35) with insurance for transit within the U.S. contiguous 48 states. For international shipments, please contact LaserStar Technologies directly.

Eyeglasses - IR Laser Safety (OD 7+ / VLT 60%)

Designed for fiber laser marking and welding applications, these IR Laser Safety Glasses provide high optical density shielding (OD>7+ at 1000-1095nm) to safeguard your eyes from intense infrared radiation. With 60% Virtual Light Transmission (VLT), these glasses allow for clearer visibility while maintaining maximum laser protection in industrial settings.

Key Features:

✅ Ideal for Fiber Laser Markers & Welders

✅ High Optical Density (OD) Ratings for Maximum Protection:

- 1000 - 1095nm OD>7+

- 830 - 980nm OD>5+

- 800 - 1100nm OD>4+

✅ Certified Laser Protection: - 800 - 1100nm DIR LB4

- 830 - 980nm DIR LB5

- 1000 - 1095nm D LB5 + IR LB7 LP S CE

✅ Clear Vision & Safety: 60% VLT for enhanced visibility

Stay protected while working with fiber laser welding and marking systems with these certified IR Laser Safety Glasses, designed for optimal clarity and defense against infrared radiation.