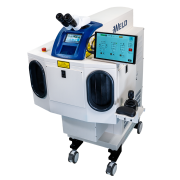

1902-MFX iWeld Industrial CNC Welding Workstation with MotionFX® (80W or 100W)

The iWeld 1902 MFX Series CNC Laser Welder integrates MotionFX® CNC X/Y/Z-Rotary technology, delivering pinpoint accuracy and multi-axis precision. This industrial laser welding system supports Manual Mode, Semi-Manual Mode, and Full CNC Automation Mode, ensuring unmatched control, stability, and efficiency for diverse welding applications.

Key Features:

✔ Powerful, Stable, & Robust Pedestal Design

✔ MotionFX® CNC X/Y/Z with Optional Rotary Device

✔ Manual, Semi-Manual, Teach, & Full CNC Modes

✔ 80W or 100W Power with 11kW Peak Pulse Power

✔ Soft-Touch® Beam Profiling & First Pulse Suppression

✔ Variable Speed Fan & Closed-Loop Cooling System

✔ User-Friendly Touchscreen & Chamber Joystick Controls

✔ Preventive Maintenance Alerts & Auto Energy Save Mode

✔ Multiple Microscope Options Available

The iWeld 1902 MFX CNC Laser Welder is FDA (CDRH), UL, and CE certified for global safety compliance.

Note:

The above price DOES NOT include a microscope. Please select your preferred microscope and add it to the system. Your revised total price will be displayed below.

3905-T30 FiberStar CNC Laser Welding Workstation / Class 1 (150W - 600W)

The FiberStar 3905 Series T30 CNC Laser Machining Workstation is a high-precision, air-cooled laser machining solution designed for industrial, aerospace, medical, and jewelry applications. Featuring a programmable 4-Axis CNC controller (X/Y/Z + optional Rotary) and an integrated computer with a Windows operating system, this turnkey laser system comes fully equipped with LaserStar Machining Software and DXF-GCODE Conversion Software for streamlined operation.

Key Applications of the FiberStar 3905 Series:

✔ Medical Devices & Surgical Instruments

✔ Tool & Die Manufacturing

✔ Aerospace & Electronics Components

✔ Prototyping & Micro-Component Fabrication

✔ Automotive Precision Parts

✔ Complex Industrial Alloys & Materials

✔ Jewelry Manufacturing (Gold, Silver, Platinum, Titanium)

✔ Ceramics & Plastics Processing

System Highlights:

✔ Programmable 4-Axis CNC Controller (X/Y/Z & Optional Rotary)

✔ Integrated Computer with Windows OS

✔ Preloaded with LaserStar Machining & DXF-GCODE Conversion Software

✔ Air-Cooled System for Efficient Operation

✔ Precision Machining for Industrial & High-Tech Applications

✔ Customizable Configurations to Meet Production Needs

As a turnkey solution provider, LaserStar’s Application Specialists will evaluate your specific laser machining requirements, define your application goals, verify the correct technology, and configure a custom system to achieve optimal results.

Contact LaserStar Technologies today to discuss your customized project, establish a statement of work, and receive a formal quotation tailored to your production requirements.

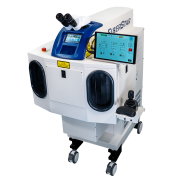

7601-MFX FiberStar Industrial CNC Welding Workstation with MotionFX® (150W or 300W)

The FiberStar 7601 Series CNC Laser Welder integrates MotionFX® precision motion control technology, delivering high-accuracy, high-speed welding capabilities. Featuring state-of-the-art laser resonator technology, this system ensures optimal performance, increased throughput, and enhanced electrical efficiency. Its air-cooled, space-saving design and solid-state diodes provide instantaneous power with no warm-up time required, maximizing uptime and productivity.

System Highlights:

✔ MotionFX® Precision Motion Control for High-Accuracy Welding

✔ High Peak Power & Optimized Throughput

✔ Air-Cooled, Compact, & Energy-Efficient Design

✔ Solid-State Diodes – Instant Power with No Warm-Up Time

✔ Seamless Integration for CNC & Automated Applications

The FiberStar 7601 Series is built for industrial, high-precision laser welding, making it the ideal choice for advanced manufacturing and CNC-integrated applications.

Contact LaserStar Technologies today to discuss your welding project, define application requirements, and receive a customized system solution tailored to your production needs.

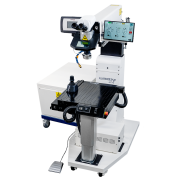

7803 LaserStar Industrial CNC Open Welding Workstation with MotionFX® (150W)

The LaserStar 783 CNC Open Welding Workstation is an advanced, joystick-controlled 3-axis laser welding system, featuring LaserStar’s MotionFX G-code programming software. Its open workspace design makes it ideal for a variety of applications, including plastic injection mold repair, die and tooling restoration, electronic component welding, high-precision industrial assemblies, and pressure-sensitive hermetic laser sealing.

With LaserStar's cutting-edge laser technology, minimal heat is applied at the weld point, allowing for highly precise welding as close as <0.025mm to intricate, heat-sensitive components, while maintaining unmatched pulse stability.

Key Features:

✅ Portable Joystick Control for precision handling

✅ Robust Work Table with Z-Axis Adjustment (Supports up to 200 lbs / 91 kg)

✅ MotionFX® CNC X/Y/Z System for programmable welding

✅ Manual, Semi-Automatic & Full Automatic Modes

✅ Teach-Mode Enabled for ease of use

✅ Programmable Touch Screen Display

✅ Joystick with Fire Button Control Logic

✅ High-Accuracy X/Y/Z Axis Speed Control

✅ Optional Rotary Device for advanced applications

✅ Integrated Windows PC with MotionFX™ Software

✅ Telescoping Laser Rail Assembly for flexibility

✅ Tilting Optical Beam Path Head (Optional)

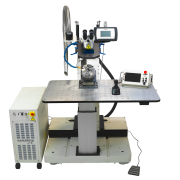

8803 FiberStar Industrial CNC Open Welding Workstation with MotionFX® (150W - 600W)

The CNC Welding Workstation 8803 Series is a cutting-edge, joystick-controlled 3-axis laser welding system equipped with LaserStar’s MotionFX G-code programming software. Its open workspace design makes it ideal for a variety of applications, including plastic injection mold repair, die and tooling restoration, intricate electronic component assembly, high-precision industrial welding, pressure-sensitive hermetic sealing, and more.

One of the key advantages of the CNC Welding Workstation 8803 Series is its ability to generate minimal heat at the weld point, allowing users to weld as close as <0.025mm to complex, heat-sensitive components while maintaining exceptional pulse stability of +/- 1%.

Features:

- Advanced, High-Precision Design

- 3-Axis Coordinated Motion for Accuracy

- Manual & CNC Programming Modes

- CW & Pulse Laser Output Options

- Available in 150W, 300W, 450W & 600W Power Levels

Experience superior welding precision and efficiency with the CNC Welding Workstation 8803 Series, designed for industrial applications that demand accuracy and reliability.

8900 FiberStar Industrial CNC Open Welding Workstation w/MotionFX® (150W - 600W)

The FiberStar 8900 Series CNC Welding Workstation delivers cutting-edge fiber laser technology for high-precision welding applications. Designed for industrial-grade performance, this system provides high peak power, optimal throughput, and enhanced electrical efficiency. The air-cooled, space-saving design ensures maximum uptime, while solid-state diodes deliver instantaneous power with no warm-up time required.

Key Applications of the FiberStar 8900 Series:

✔ Medical Device & Instrument Welding

✔ Aerospace & Automotive Component Fabrication

✔ Electronics & Micro-Welding Applications

✔ Battery & Energy Storage Solutions

✔ Industrial Tooling & Custom Metal Fabrication

✔ Jewelry & Precious Metal Welding

System Highlights:

✔ Advanced Fiber Laser Resonator Technology

✔ High Peak Power for Precision Welding

✔ Optimized Throughput for Increased Productivity

✔ Air-Cooled, Compact & Energy-Efficient Design

✔ Solid-State Diodes – No Warm-Up Time Required

✔ CNC Control for Automated Welding Processes

The FiberStar 8900 Series is built to handle high-precision, industrial welding applications, ensuring repeatable, high-quality results across a range of manufacturing environments.

Contact LaserStar Technologies today to discuss your welding project, define application requirements, and receive a customized system solution tailored to your production needs.

LaserStar Industrial CNC Open Welding Workstation with MotionFX® (150W)

The LaserStar 7902 Series CNC Welding Workstation features state-of-the-art laser resonator technology, delivering high peak power, optimal performance, and enhanced throughput. Designed with a space-saving, air-cooled design, this system ensures higher uptime, improved electrical efficiency, and seamless precision welding for a wide range of applications.

Precision & Performance:

✔ High Peak Power for Ultra-Fine Laser Welding

✔ Minimal Heat Generation – Weld Within 0.025mm of Heat-Sensitive Parts

✔ Stereo Microscope with Cross-Hair Alignment for Precision Positioning

✔ Air-Cooled, Energy-Efficient Design – No Warm-Up Time Required

✔ Ergonomic Workstation for Operator Comfort & Flexibility

Designed for Advanced Laser Welding Applications:

- Spot Welding, Seam Welding, & Micro Welding

- Mold Repair & Battery Welding

- Precision Welding for Complex Alloys & Heat-Sensitive Parts

The LaserStar 7902 Series CNC Welding Workstation offers a competitive advantage for operators looking to harness the power of precision laser welding while maintaining maximum flexibility for industrial and repair applications.

Note:

The above price includes the required custom shipping container and prepaid freight with insurance for transit within the U.S. contiguous 48 states. For international purchase shipments, please contact LaserStar Technologies directly.