O

PEN

W

ORK

S

PACE

W

ELDING

W

ORKSTATION

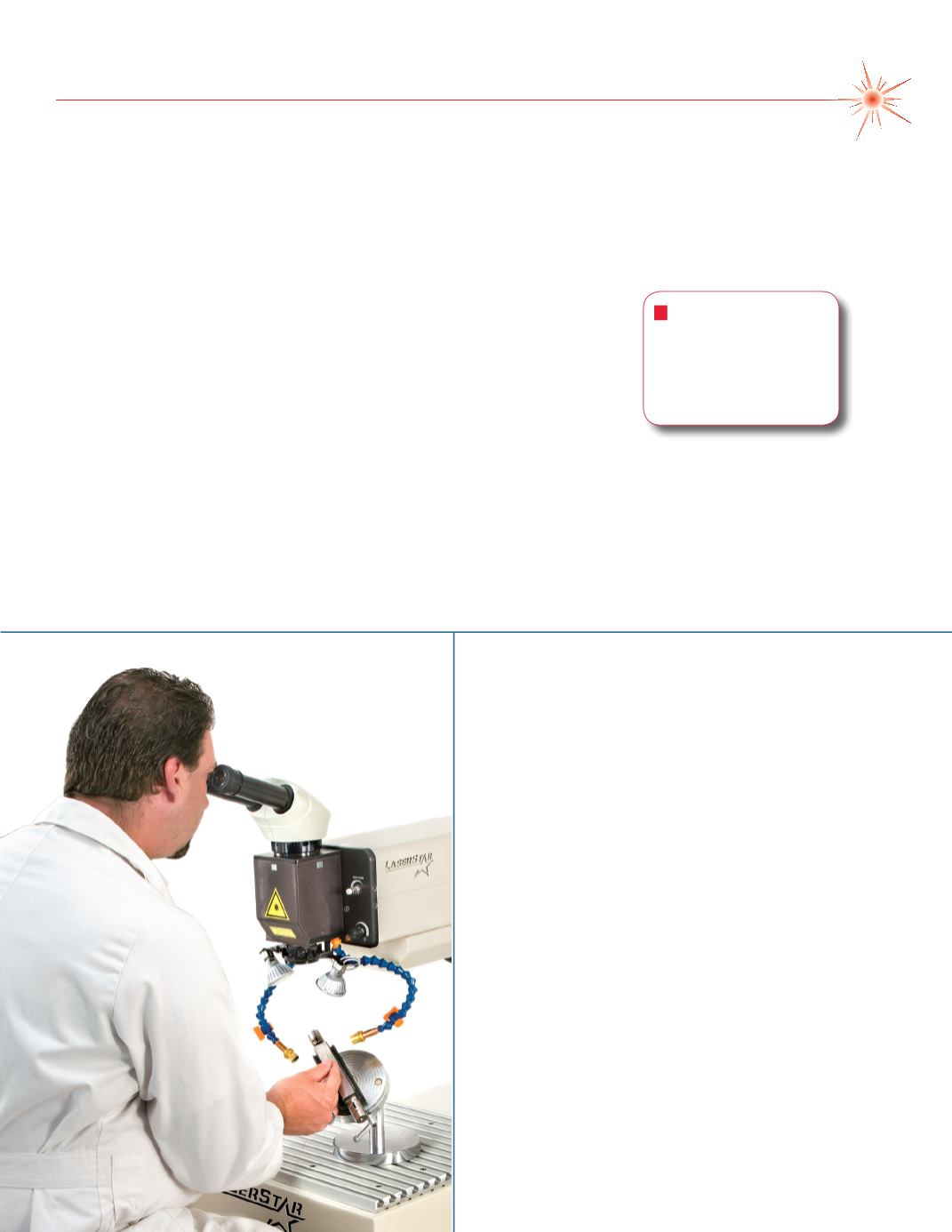

7700 Series with Universal Jig

Today’s mold repair micro-welding laser industry is characterized by rapidly changing, ever-evolving

customer demands and intense competition. Innovative ideas, successful designs and a strong

commitment to superior quality and performance are the fundamentals of LaserStar Technologies

Corporation.

LaserStar’s Universal Jig offers a significant, competitive

advantage for today’s operators looking to unleash the power

of hot light, benefit from a comfortable, ergonomic design

and ensure optimal platform flexibility for the widest range of

on-site repair applications.

Our commitment to electrical design efficiency ensures the highest level of hot-light energy transfer

from the LaserStar source through the welding zone. The result is a significant pulse energy advantage

while maintaining minimum water cooling temperatures and 24-hour operational performance.

LaserStar Workstations are ideal for a wide range of complex alloys and applications.

26

LaserStar welding systems are ideal for a wide range of

large plastic injection mold, tool & die maintenance and

repair applications.

•

Lay a bead from .0025” / 0.40mm

•

Repair slots, pockets, radius contours and angles

•

Repair polished, textured and engraved surfaces

•

Repair thin walls with little or no warping

•

Repair parting line edges and heat sensitive areas

•

Alloys include tool steel, aluminum, copper,

titanium and powdered metals

The LaserStar produces a high quality result, reduces

the amount of handwork required before polishing and

practically eliminates sink lines.

HIGHLIGHTS

Open Workspace Design

Portable Precision Table

Ideal for Large Parts

Motorized X / Y / Z Axis