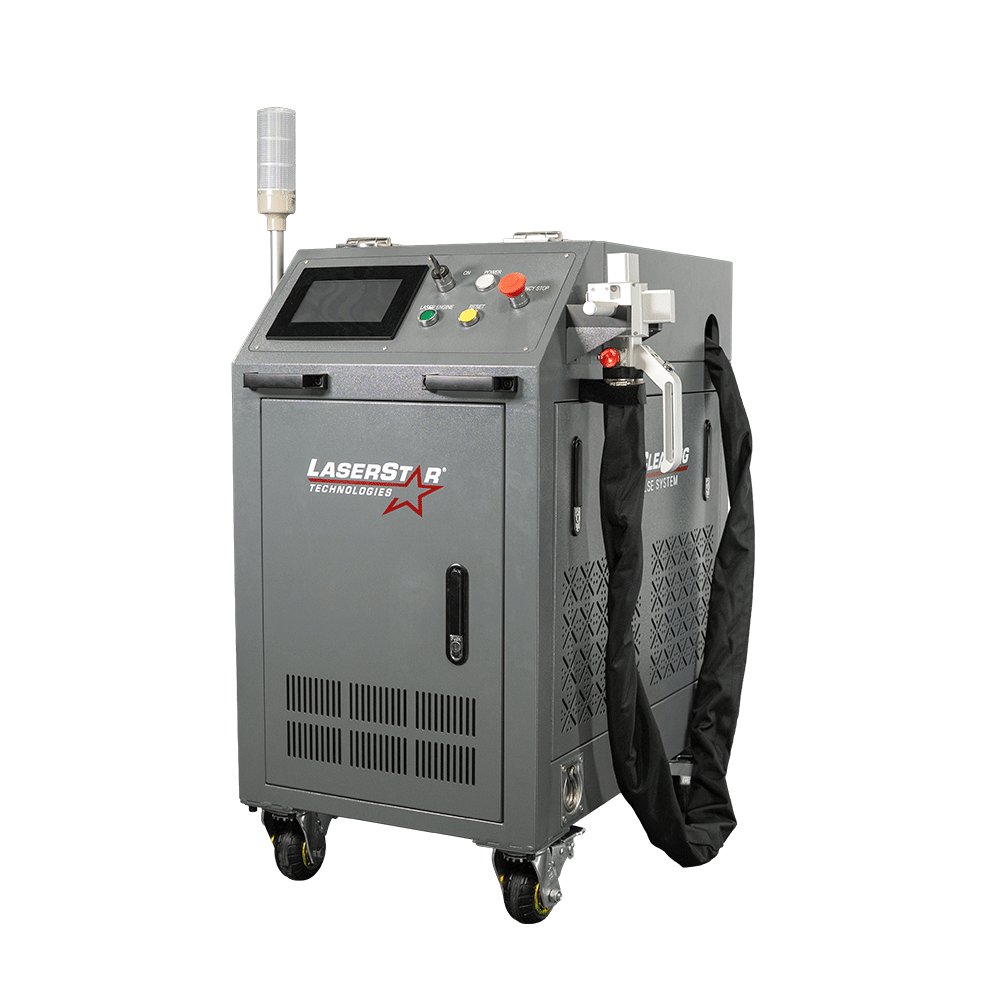

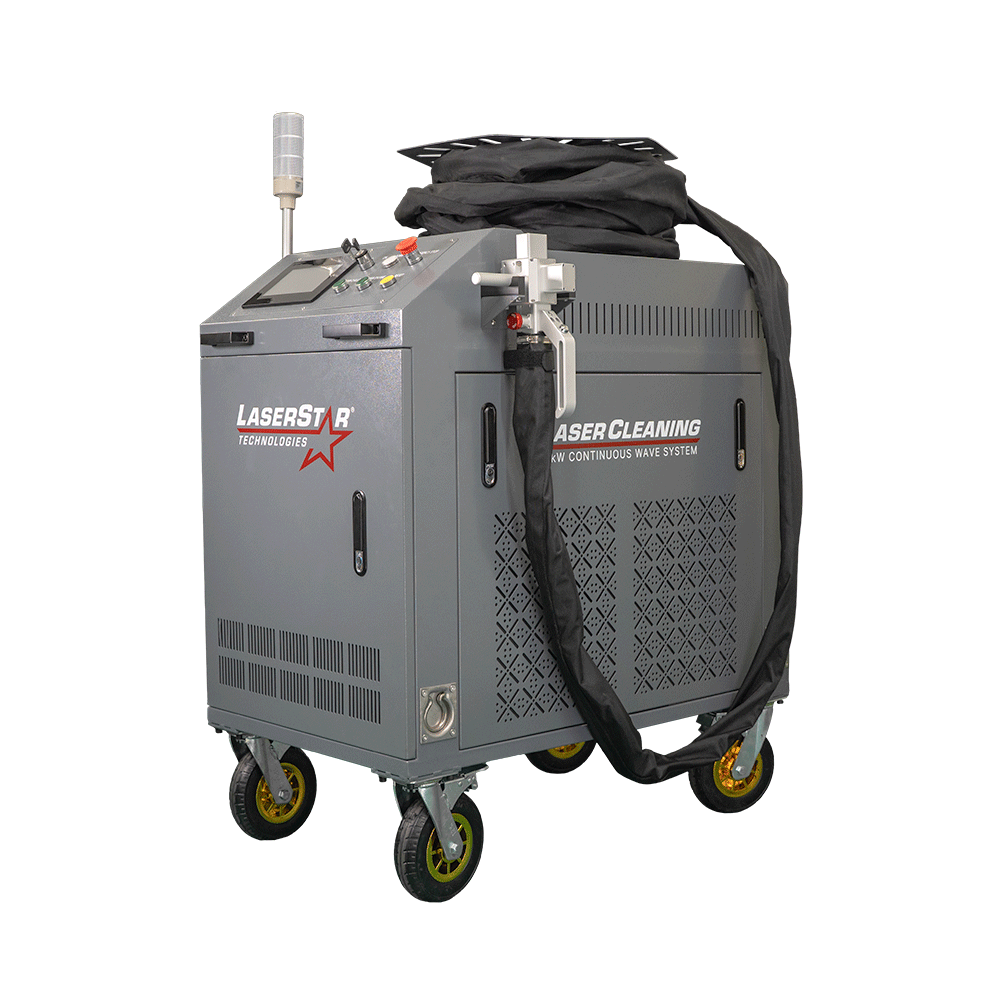

LaserStar® Industrial Laser Cleaner (500W)

4103-M Series

Part# 577-413-M-500-5-254FS

CALL FOR QUOTE

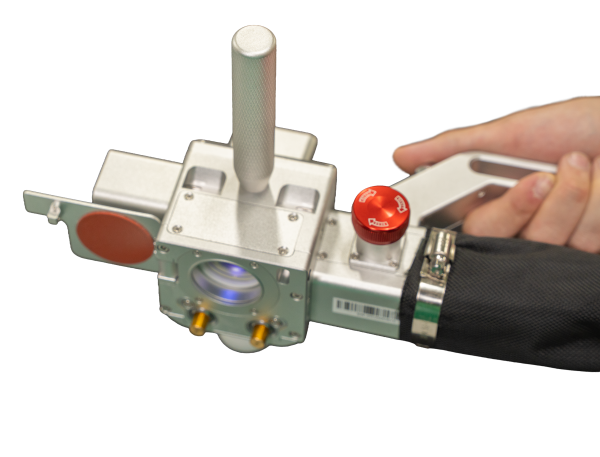

The LaserStar 4103-M Series 500W Industrial Laser Cleaner is a powerful, portable pulse laser solution for removing contaminants, coatings, rust, and oxides from various materials without causing damage to the underlying surface. Its ergonomic portable design enhances mobility, making it an excellent choice for industrial applications requiring precision cleaning with minimal environmental impact. This versatile handheld laser cleaner efficiently works on delicate or complex surfaces, ensuring safe and effective cleaning.

- Robust Commercial Design with Back Reflection Isolator

- Detachable Handheld Scanner with LED Red Pointers and E-Stop / 5 meter cable

- 500 Watt Water Cooled Pulse MOPA Fiber Laser System

- Select 5 milli-joule Pulse Energy Output

Applications of the LaserStar 4103-M Series 500W Industrial Laser Cleaner :

- Rust, Corrosion, Paint & Coating Removal

- Surface Preparation for Welding or Bonding

- Plastic & Rubber Mold Cleaning

- Oil, Grease & Oxide Layer Removal

- Deburring, Surface Texturing & Finishing

- PCB Cleaning & Anilox Print Roll Cleaning

- Microbial Cleaning, Sterilization & Decontamination

The LaserStar 4103-M Series 500W Industrial Laser Cleaner offers an eco-friendly, non-abrasive cleaning solution with exceptional precision and efficiency for a wide range of industries.

Contact LaserStar Technologies today to discuss your laser cleaning project, define application requirements, and receive a customized system solution tailored to your production needs.

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Features & Benefits

- Additional information

- Technical Specifications

Description

LaserStar Industrial Laser Cleaner 500W

is a robust, high-performance laser cleaning system engineered for demanding industrial environments where speed, consistency, and surface integrity are paramount. Positioned between lower-power bench or handheld units and ultra-high power continuous systems, this 500 W laser cleaner offers a powerful balance: strong cleaning capability without being excessively large or energy hungry.

Why Choose a 500W Laser Cleaning System?

In many industrial settings—such as mold maintenance, tool refurbishment, metal repair, and surface preparation—the removal of rust, coatings, paint, oxidation, adhesives, or residue must be efficient but gentle. Traditional mechanical, chemical, or abrasive cleaning methods often damage the substrate or leave behind residues. A LaserStar Industrial Laser Cleaner 500W enables non-contact, precise cleaning that preserves the base material. Because there are no consumables, media, or chemicals, the operating costs and waste generation are significantly reduced.

The 500 W configuration provides sufficient power to clean larger areas at higher speeds compared to smaller handheld systems, while maintaining control and minimizing thermal impact on sensitive substrates. This makes it a popular choice for shops and repair facilities that need more throughput but don’t require extreme continuous wave (CW) cleaning systems.

Core Features and Capabilities

Although specific technical specifications are not publicly listed in detail, we can infer the expected features and benefits based on LaserStar’s product portfolio and industrial laser cleaning trends:

-

High Cleaning Throughput: Capable of removing coatings, rust, paint, or oxidation efficiently across surfaces that smaller units would struggle with.

-

Precise Beam Control: With proper optics and scanning, operators can localize cleaning zones to avoid damaging adjacent features.

-

Minimal Heat Diffusion: The laser energy is absorbed within a narrow zone, reducing heat transfer and preventing warping or stress in heat-sensitive components.

-

Consumable-Free Process: No abrasive media, chemicals, or waste residues beyond what is removed from the surface.

-

Integrated Safety & Enclosure Options: Likely includes shielding, interlocks, and fume extraction compatibility to maintain safe operation in industrial environments.

-

User Interface & Control: Adjustable parameters (e.g., power, scanning speed, overlap) to tune cleaning for different materials and contamination types.

-

Scalable & Serviceable Design: Modules or optics can be maintained or upgraded, extending system life and performance.

Applications & Industry Use Cases

The LaserStar Industrial Laser Cleaner 500W finds relevance in many sectors:

-

Mold & Die Maintenance: Stripping residue, coatings, or buildup from complex cavity surfaces without damaging fine features.

-

Tool & Part Refurbishment: Cleaning worn or oxidized tools, dies, or worn parts to restore dimension or surface finish.

-

Aerospace & Automotive: Removing protective coatings, oxidation, or welding spatter from structural or functional parts.

-

Electronics & Precision Components: Cleaning contacts, connectors, or housings where contamination must be removed without abrasive contact.

-

Metal Fabrication & Manufacturing: Surface preparation before coating, bonding, or painting to ensure adhesion.

-

Heritage & Restoration: Cleaning metal artifacts or surfaces where minimal material removal is essential.

Operators in forums and industry discussions often cite 500 W as a threshold power level to reach industrial capability. One user noted that a 500 W tophat laser achieves about 1 m² per hour removal rate under heavy coatings (e.g., 400 µm epoxy) in certain conditions. Reddit While higher-power systems exist, a 500W unit hits a sweet spot for many repair, prototyping, and mid-scale production needs.

Best Practices & Integration Tips

To get the most out of your LaserStar Industrial Laser Cleaner 500W, consider:

-

Use Appropriate Optics & Scanning to tailor the beam to part geometry, avoiding hotspots or uneven cleaning.

-

Ensure Effective Fume Extraction – laser cleaning produces vaporized debris and particles that require capture and filtration.

-

Tune Parameters Carefully – power, speed, overlap, and repetition rate must be optimized for each material and contamination type.

-

Prevent Overheating – manage duty cycles or pause intervals to maintain operations without thermal shutdowns.

-

Maintain Optics & Alignment – dust on lenses or mirrors can degrade performance; periodic cleaning and calibration are essential.

-

Implement Safety Controls – shielding, interlocks, appropriate eyewear, and zone enclosures are critical for safe deployment.

Summary & Positioning

The LaserStar Industrial Laser Cleaner 500W stands as a powerful, versatile laser cleaning solution for industrial users seeking a balance between throughput, control, and surface protection. With its non-contact, consumable-free cleaning approach, it addresses the limitations of traditional methods, enabling efficient removal of coatings, rust, and contaminants while preserving substrate integrity.

For businesses engaged in mold repair, tooling, metal refurbishment, or high-precision part preparation, a 500 W laser system offers a compelling upgrade over smaller systems—delivering greater speed, cleaner results, and workflow efficiency. While not as extreme as multi-kilowatt CW cleaners, it is often more practical in terms of energy consumption, footprint, and cost.

Benefits of Laser Cleaning:

- Precision and Control: Laser cleaning offers precise control over the cleaning process, allowing for the removal of specific layers of material without damaging the underlying surface.

- Non-Abrasive and Gentle: Unlike traditional methods like sandblasting or chemical cleaning, laser cleaning is non-abrasive. This means it doesn’t wear down or alter the surface of the material being cleaned.

- Environmentally Friendly: Laser cleaning is a dry process that doesn’t require the use of chemicals, solvents, or abrasive materials, reducing environmental impact and waste.

- Cost-Effective: Over time, laser cleaning can be more cost-effective due to lower maintenance requirements, reduced need for consumables, and the ability to automate the process.

- Versatility: It can be used on a wide range of materials, including metals, ceramics, plastics, and composites, making it suitable for various industries such as aerospace, automotive, and conservation.

- Safety and Cleanliness: Laser cleaning reduces the risk of contamination and exposure to harmful chemicals, improving safety for operators and reducing the need for protective equipment.

- Reduced Downtime: The precision and efficiency of laser cleaning can minimize downtime in industrial settings, allowing for faster turnaround times and increased productivity.

- Minimal Residue: The process typically leaves minimal residue, which simplifies the post-cleaning process and ensures a cleaner work environment.

- Automation Compatibility: Laser cleaning systems can be easily integrated into automated production lines, enhancing efficiency and consistency in cleaning tasks.

- Long-Term Savings: The durability of laser cleaning equipment and the reduction in consumable costs can lead to significant long-term savings.

Additional information

| Series | 4103-M |

|---|---|

| 4103-M | 4103-M Series |