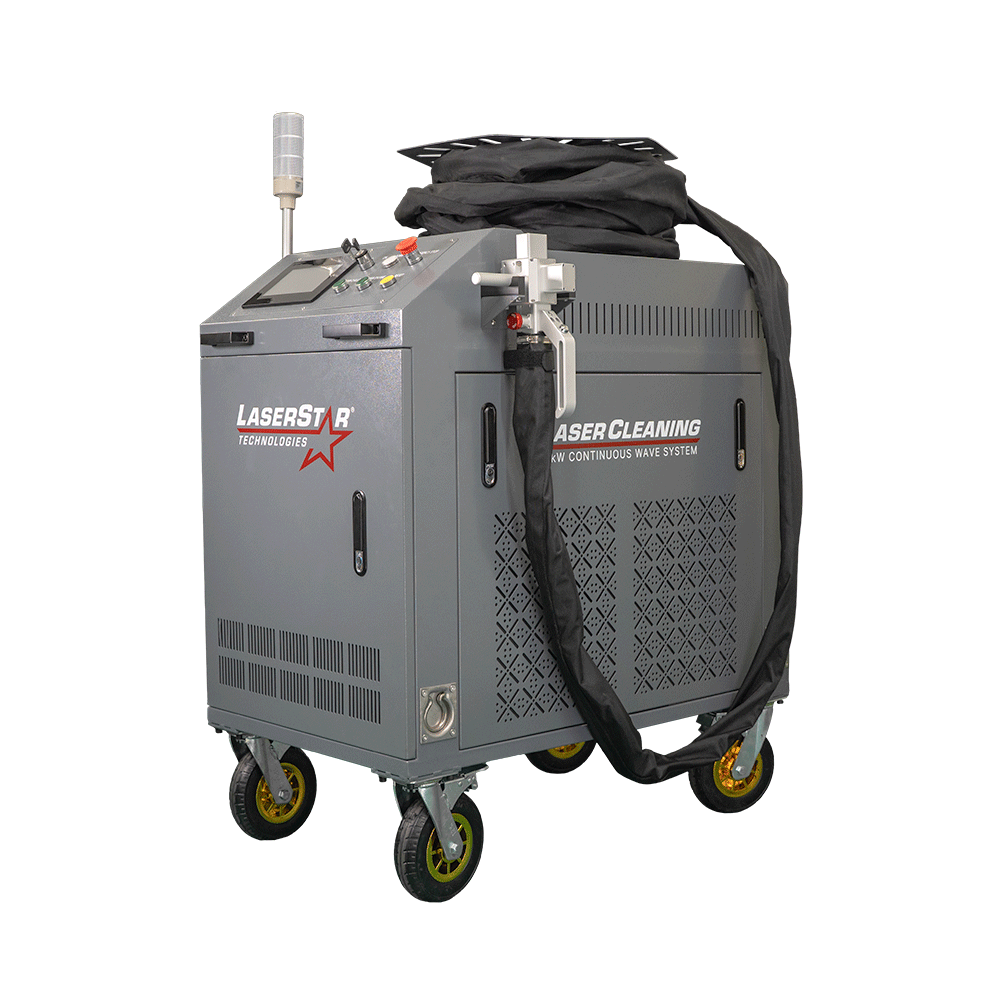

LaserStar® Industrial Pulse Laser Cleaner (300W)

4103-M Series

Part# 577-413-M-300-5-254FS

CALL FOR QUOTE

The LaserStar 4103-M Series 300W Industrial Pulse MOPA Laser Cleaner is a powerful, portable pulse laser solution for removing contaminants, coatings, rust, and oxides from various materials without causing damage to the underlying surface. Its ergonomic portable design enhances mobility, making it an excellent choice for industrial applications requiring precision cleaning with minimal environmental impact. This versatile handheld laser cleaner efficiently works on delicate or complex surfaces, ensuring safe and effective cleaning.

- Robust Commercial Design with Back Reflection Isolator

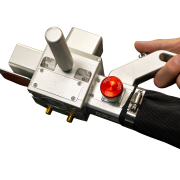

- Detachable Handheld Scanner with LED Red Pointers and E-Stop

- 300 Watt Air Cooled Pulse MOPA Fiber Laser System

- Provides a 5 milli-joule Pulse Energy Output

Applications of the LaserStar 4103-M Series 300W Industrial Pulse MOPA Laser Cleaner :

- Rust, Corrosion, Paint & Coating Removal

- Surface Preparation for Welding or Bonding

- Plastic & Rubber Mold Cleaning

- Oil, Grease & Oxide Layer Removal

- Deburring, Surface Texturing & Finishing

- PCB Cleaning & Anilox Print Roll Cleaning

- Microbial Cleaning, Sterilization & Decontamination

The LaserStar 4103-M Series 300W Industrial Laser Cleaner offers an eco-friendly, non-abrasive cleaning solution with exceptional precision and efficiency for a wide range of industries.

Contact LaserStar Technologies today to discuss your laser cleaning project, define application requirements, and receive a customized system solution tailored to your production needs.

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Features & Benefits

- Additional information

- Technical Specifications

Description

LaserStar Industrial Laser Cleaner 300W

is a premium pulsed laser cleaning solution engineered for industrial environments where precision, repeatability, and surface safety are critical. This 300 W unit offers a balance of power and control, making it highly effective for removing rust, coatings, oxidation, and contaminants from surfaces without damaging the underlying material. As a consumable-free, non-contact cleaning method, it helps reduce maintenance overhead, improve productivity, and preserve component integrity.

Why Choose a 300W Pulsed Laser Cleaner?

In many industrial workflows—such as mold repair, tool refurbishment, metal surface preparation, or legacy part restoration—traditional cleaning methods (abrasive blasting, chemicals, mechanical removal) can introduce damage, substrate wear, or contamination. The LaserStar Industrial Laser Cleaner 300W instead uses pulsed laser energy to ablate unwanted layers precisely, leaving the base material intact.

The pulsed mode allows bursts of high peak power with limited thermal diffusion. This enables the system to remove thin coatings or corrosion layers while avoiding excessive heating of the substrate. For delicate surfaces, fine features, or heat-sensitive alloys, this is a major advantage over bulk mechanical or chemical cleaning.

Core Features & Capabilities

Although detailed specs are not in public view, the LaserStar Industrial Laser Cleaner 300W is listed among LaserStar’s line of industrial pulse laser cleaners. LaserStar Technologies It likely shares many attributes common to pulsed laser cleaning solutions, such as:

-

High peak pulse energy tailored for effective ablation

-

Adjustable repetition rate to match different materials and contamination thickness

-

Precise beam control and scanning optics

-

User interface to vary parameters (power, speed, overlap) for optimal cleaning

-

Safety interlocks, shielding, and optical design to protect operators

-

Modular, serviceable optical path and components

In the broader industry, 300 W pulsed laser cleaners are considered mid-to-high performance. For example, comparative 300 W systems in the market aim at “industrial grade” cleaning of rust, paint, and heavy coatings. haotianlasers.com+1 These systems are often air-cooled or include moderate thermal management, optimized for robust use.

Applications & Use Cases

The LaserStar Industrial Laser Cleaner 300W is ideal for many demanding use cases:

-

Mold & Die Maintenance – Removing burnt residue, silica coatings, or polishing build-up from cavities without altering fine mold details

-

Tool & Part Refurbishment – Stripping oxidation or coatings from cutting tools, jigs, or repair parts

-

Metal Fabrication & Repair – Cleaning weld spatter, heat tint, or scale before rework or inspection

-

Surface Preparation – Preparing metal parts for coating, painting, or bonding by exposing clean bare metal

-

Electronics & Precision Components – Cleaning contacts, housings, or connectors where minimal mechanical stress is required

-

Historical & Restoration Projects – Gentle cleaning of metal artifacts or heritage parts where preserving surface structure is essential

In user forums, 300 W pulsed units are used for cleaning metal rollers, rust removal, coatings, etc. Reddit Their flexibility to adjust focus, repetition rate, and scanning makes them practical in diverse shop settings.

Performance & Benefits

Adopting the LaserStar Industrial Laser Cleaner 300W brings several advantages:

-

Consumable-Free Operation — No abrasive media, chemicals, or masking needed, reducing waste and consumable cost.

-

High Precision Control — Adjustable pulses and scanning allow selective cleaning without damaging substrate or features.

-

Minimal Thermal Load — Pulsed operation reduces heat diffusion, limiting damage to adjoining areas.

-

Improved Throughput — Faster and repeatable cleaning compared to manual methods—especially for fine or hard-to-reach zones.

-

Lower Maintenance — Fewer mechanical parts or wear-sensitive components means reduced downtime.

-

Cleaner Work Environment — Laser cleaning typically produces less secondary dust or mess compared to grit blasting.

Integration & Best Practices

To fully harness the LaserStar Industrial Laser Cleaner 300W, follow these integration tips:

-

Fume Extraction & Ventilation is essential — vaporized material must be safely extracted and filtered

-

Optimize Laser Parameters (pulse energy, repetition, overlap, speed) based on material, contamination thickness, and adhesion

-

Use Proper Optics & Focus Distance — maintain correct focal distance for maximum ablation efficiency

-

Protect Surroundings — shield adjacent areas, use masking if needed to avoid stray beam exposure

-

Periodic Optic Cleaning & Calibration — dust, debris, or misalignment can degrade performance

-

Safety Controls & Interlocks — ensure proper enclosures, interlocks, and eyewear for safe usage

Summary & Positioning

The LaserStar Industrial Laser Cleaner 300W is a powerful, precise, and versatile pulsed laser cleaning solution built for industrial environments. It delivers high-efficiency surface cleaning with minimal thermal impact and without consumables, making it valuable for users needing reliable, high-precision cleaning of metals, molds, tools, and delicate components.

For workshops and facilities that demand quality, repeatability, and low maintenance in their surface cleaning processes, this 300 W pulsed laser cleaner offers a compelling upgrade over older or manual methods.

Benefits of Laser Cleaning:

- Precision and Control: Laser cleaning offers precise control over the cleaning process, allowing for the removal of specific layers of material without damaging the underlying surface.

- Non-Abrasive and Gentle: Unlike traditional methods like sandblasting or chemical cleaning, laser cleaning is non-abrasive. This means it doesn’t wear down or alter the surface of the material being cleaned.

- Environmentally Friendly: Laser cleaning is a dry process that doesn’t require the use of chemicals, solvents, or abrasive materials, reducing environmental impact and waste.

- Cost-Effective: Over time, laser cleaning can be more cost-effective due to lower maintenance requirements, reduced need for consumables, and the ability to automate the process.

- Versatility: It can be used on a wide range of materials, including metals, ceramics, plastics, and composites, making it suitable for various industries such as aerospace, automotive, and conservation.

- Safety and Cleanliness: Laser cleaning reduces the risk of contamination and exposure to harmful chemicals, improving safety for operators and reducing the need for protective equipment.

- Reduced Downtime: The precision and efficiency of laser cleaning can minimize downtime in industrial settings, allowing for faster turnaround times and increased productivity.

- Minimal Residue: The process typically leaves minimal residue, which simplifies the post-cleaning process and ensures a cleaner work environment.

- Automation Compatibility: Laser cleaning systems can be easily integrated into automated production lines, enhancing efficiency and consistency in cleaning tasks.

- Long-Term Savings: The durability of laser cleaning equipment and the reduction in consumable costs can lead to significant long-term savings.

Additional information

| Series | 4103-M |

|---|---|

| 4103-M | 4103-M Series |