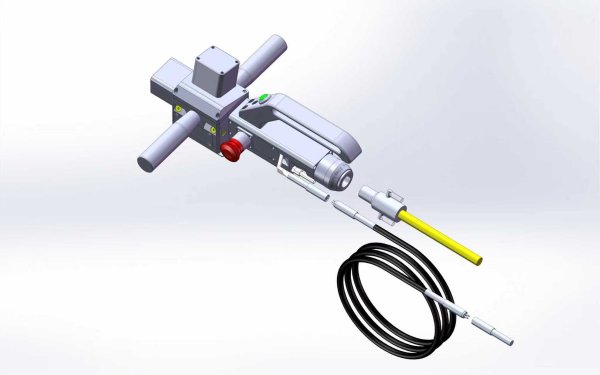

LaserStar® Industrial CW Laser Cleaner (2kW)

4103-C Series

Part# 577-413-C-2000-500FS

CALL FOR QUOTE

The LaserStar 4103-C Series 2kW CW Industrial Laser Cleaner is a powerful, heavy duty, portable continuous wave laser solution for removing contaminants, coatings, rust, and oxides from various materials without causing damage to the underlying surface. Its ergonomic portable design enhances mobility, making it an excellent choice for industrial applications requiring precision cleaning with minimal environmental impact. This versatile handheld laser cleaner efficiently works on delicate or complex surfaces, ensuring safe and effective cleaning.

- Robust Commercial Design with Back Reflection Isolator

- Modular Dual Galvo Scanner Handpiece with LED Red Pointers and E-Stop

- 2kW Water Cooled, Continuous Wave (CW) Fiber Laser System

Applications of the LaserStar 4103-M Series 2kW Industrial Laser Cleaner :

- Rust, Corrosion, Paint & Coating Removal

- Surface Preparation for Welding or Bonding

- Plastic & Rubber Mold Cleaning

- Oil, Grease & Oxide Layer Removal

- Deburring, Surface Texturing & Finishing

- PCB Cleaning & Anilox Print Roll Cleaning

- Microbial Cleaning, Sterilization & Decontamination

The LaserStar 4103-M Series 2kW CW Industrial Laser Cleaner offers an eco-friendly, non-abrasive cleaning solution with exceptional precision and efficiency for a wide range of industries.

Contact LaserStar Technologies today to discuss your laser cleaning project, define application requirements, and receive a customized system solution tailored to your production needs.

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Features & Benefits

- Additional information

Description

LaserStar Industrial CW Laser Cleaner 2 kW

is a powerful continuous-wave (CW) laser cleaning system engineered for heavy-duty industrial environments where speed, consistency, and material safety are critical. As manufacturers and repair facilities demand faster and safer surface preparation techniques, this 2 kW CW solution stands out by offering high throughput, minimal thermal damage, and versatile cleaning across a broad range of materials and contaminants.

What Makes It an Industrial-Grade Cleaner

The LaserStar Industrial CW Laser Cleaner 2 kW is built to withstand the rigors of industrial use. Unlike pulsed systems that deliver energy in bursts, CW lasers provide a steady continuous output—making them ideal for aggressive cleaning tasks such as heavy rust removal, thick coating stripping, fouling removal, and large surface preparation. The constant energy input enables uniform material ablation with fewer dwell spots or overlaps.

Because of this continuous operation mode, the system is suited for large parts, structural components, tanks, molds, and production lines, where speed and consistency are crucial. It can operate for longer durations without the thermal cycling typical of pulsed systems, which reduces thermal stress on the machine and the substrate.

Key Capabilities & Advantages

-

High Throughput Cleaning

The 2 kW power level allows fast removal of heavy coatings, rust, oxides, paints, adhesives, and other surface contaminants over wide areas. -

Minimal Substrate Damage

The continuous wave operation, when paired with precise optics control, limits heat diffusion into the substrate. This makes it safer for sensitive metals and alloys, especially in repair or restoration workflows. -

Eco-Friendly, Consumable-Free Process

No use of abrasives, chemicals, or solvents reduces waste and operating costs while improving safety and environmental compliance. -

Consistency & Smooth Finish

The system maintains a steady laser beam, reducing variations and hotspots. The result is a more consistent cleaning finish across the surface. -

Versatility Across Materials

It can be used on various metals (steel, stainless, aluminum), tool steels, composites, and even certain coatings and surface finishes commonly encountered in manufacturing, maintenance, and refurbishment.

Applications & Use Cases

The LaserStar Industrial CW Laser Cleaner 2 kW is applicable in many industries:

-

Rust & Scale Removal: For heavy oxidation on structural steel, pipelines, machinery components, large molds, and more.

-

Paint & Coating Stripping: Efficient removal of powder coatings, paint, anti-corrosion coatings, and layered finishes without mechanical abrasion.

-

Surface Preparation: Preparing substrates for bonding, welding, or recoating by exposing clean base metal.

-

Residue & Sublayer Removal: Removing adhesives, gums, or residue from molds, tooling, or older coatings.

-

Restore & Refurbish: Reconditioning of parts, molds, and assemblies in automotive, aerospace, industrial machinery, or energy sectors.

-

Cultural & Heritage Restoration: Gentle cleaning of metals or metal surfaces in restoration projects where uniformity and minimal surface impact are critical.

Operating & Integration Considerations

To leverage the full capability of the LaserStar Industrial CW Laser Cleaner 2 kW, proper integration and operation are key:

-

Cooling & Thermal Management: Continuous operation demands effective cooling. The system likely incorporates water or closed-loop cooling to manage heat in the laser head and optics.

-

Beam Delivery & Optics: Precision optics and beam shaping are critical to focus and direct the laser energy while avoiding substrate damage.

-

Control Interface: A user interface for adjusting power, scan speed, overlap, and patterning ensures adaptability across different materials and tasks.

-

Safety & Enclosure: Because CW lasers operate continuously, safety measures like enclosures, shutters, interlocks, and proper laser eyewear are mandatory.

-

Automation Compatibility: The system can be integrated into automated production lines or robotic arms, enabling repeatable, consistent cleaning operations.

Maintenance, Efficiency, & ROI

-

Reduced Consumables: No abrasive media or chemicals lower running cost and cleanup overhead.

-

Lower Downtime: Faster cleaning speeds mean less process interruption.

-

Extended Equipment Life: By avoiding abrasive methods or harsh chemicals, the substrate and tooling experience less mechanical wear or chemical degradation.

-

High ROI Potential: For operations with frequent cleaning or refurbishment needs, the efficiency gains can translate to significant savings over time.

Summary & Product Positioning

The LaserStar Industrial CW Laser Cleaner 2 kW is engineered for demanding industrial cleaning tasks where speed, consistency, and material safety matter most. Its continuous wave operation, high power, and optimized optics deliver efficient removal of coatings, rust, and contaminants, while preserving underlying surfaces. This system is an ideal choice for manufacturers, repair shops, and refurbishment facilities looking to modernize surface cleaning workflows, minimize consumable costs, and maintain high throughput with dependable performance.

Benefits of Laser Cleaning:

- Precision and Control: Laser cleaning offers precise control over the cleaning process, allowing for the removal of specific layers of material without damaging the underlying surface.

- Non-Abrasive and Gentle: Unlike traditional methods like sandblasting or chemical cleaning, laser cleaning is non-abrasive. This means it doesn’t wear down or alter the surface of the material being cleaned.

- Environmentally Friendly: Laser cleaning is a dry process that doesn’t require the use of chemicals, solvents, or abrasive materials, reducing environmental impact and waste.

- Cost-Effective: Over time, laser cleaning can be more cost-effective due to lower maintenance requirements, reduced need for consumables, and the ability to automate the process.

- Versatility: It can be used on a wide range of materials, including metals, ceramics, plastics, and composites, making it suitable for various industries such as aerospace, automotive, and conservation.

- Safety and Cleanliness: Laser cleaning reduces the risk of contamination and exposure to harmful chemicals, improving safety for operators and reducing the need for protective equipment.

- Reduced Downtime: The precision and efficiency of laser cleaning can minimize downtime in industrial settings, allowing for faster turnaround times and increased productivity.

- Minimal Residue: The process typically leaves minimal residue, which simplifies the post-cleaning process and ensures a cleaner work environment.

- Automation Compatibility: Laser cleaning systems can be easily integrated into automated production lines, enhancing efficiency and consistency in cleaning tasks.

- Long-Term Savings: The durability of laser cleaning equipment and the reduction in consumable costs can lead to significant long-term savings.

Additional information

| Series | 4103-C |

|---|