E350 LASERSTAR FUME EXTRACTOR w/Hose Kit

Part# 648-249-35-1 (120V) / 648-249-35-2 (230V)

$1,650.00

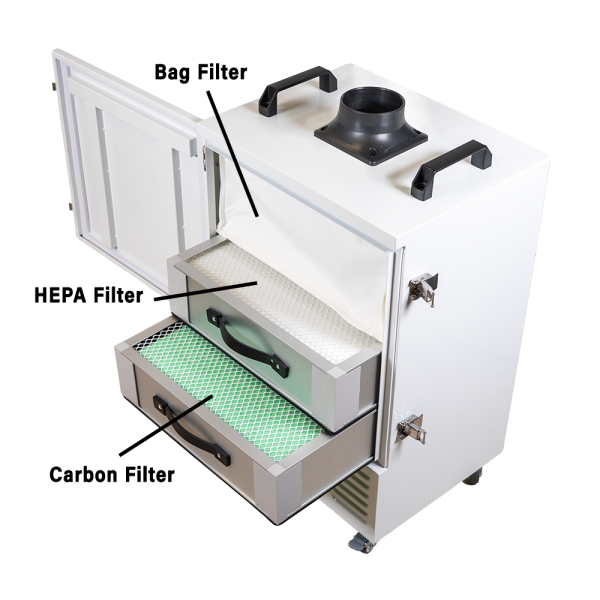

The E350 Fume Extractor Exhaust Unit is a powerful, heavy duty vacuum system designed for efficient removal of large, heavy particles. Engineered with a brushless high-speed turbine and 430 M³/h airflow, it delivers superior suction and filtration for continuous usage in demanding environments. The unit includes HEPA and odor filters, capturing 99.97% of fine particles while removing unwanted fumes.

Key Features of the Heavy Particle Vacuum Exhaust Unit:

Compact, Robust, Heavy Duty Design

Top Rated 430 M³/h for Powerful Suction

HEPA Filter Captures 99.97% of Fine Particles

Odor Carbon Filter Effectively Removes Fumes

Enhanced Noise Reduction Produces < 53dB

Brushless High-Speed Turbine for Long-Lasting Performance

Interchangeable 2 Meter PVC Hose or Flexible Hard Plastic Hose for Versatile Use

Disposable Bag Filters Capture Particles & Precious Metals for Easy Refining

Two Models Available: 120V or 220V Supply Circuits

One Year Limited Warranty

This Heavy Particle Vacuum Exhaust Unit is an excellent solution for welding, cutting, soldering, cleaning, marking & engraving applications requiring powerful and reliable filtration for large debris and fine particles.

Note: The listed price includes $155 prepaid UPS Ground Freight (990-F-249-35) with insurance for transit within the U.S. contiguous 48 states. For international shipments, please contact LaserStar Technologies directly.

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Product Brochure

- Additional information

Description

E350 Fume Extractor Vacuum Exhaust System

is LaserStar’s heavy-duty solution designed to safely and effectively manage the by-products of laser welding, marking, engraving, cutting, or cleaning processes. When you operate laser systems, particularly in enclosed or workshop environments, fumes, dust, smoke, and airborne particulate matter are inevitable. Without proper extraction and filtration, these contaminants can degrade air quality, harm sensitive components, and present health or safety risks. The E350 Fume Extractor Vacuum Exhaust System addresses these challenges with a well-engineered blend of suction power, filtration stages, and robust construction.

Core Performance & Features

The E350 Fume Extractor Vacuum Exhaust System is built around a brushless high-speed turbine capable of delivering airflow up to 430 m³/h. This strong suction is essential for capturing heavier particles and smoke before they disperse. The unit is engineered for continuous use in demanding industrial settings, ensuring reliability and consistent performance. LaserStar Technologies

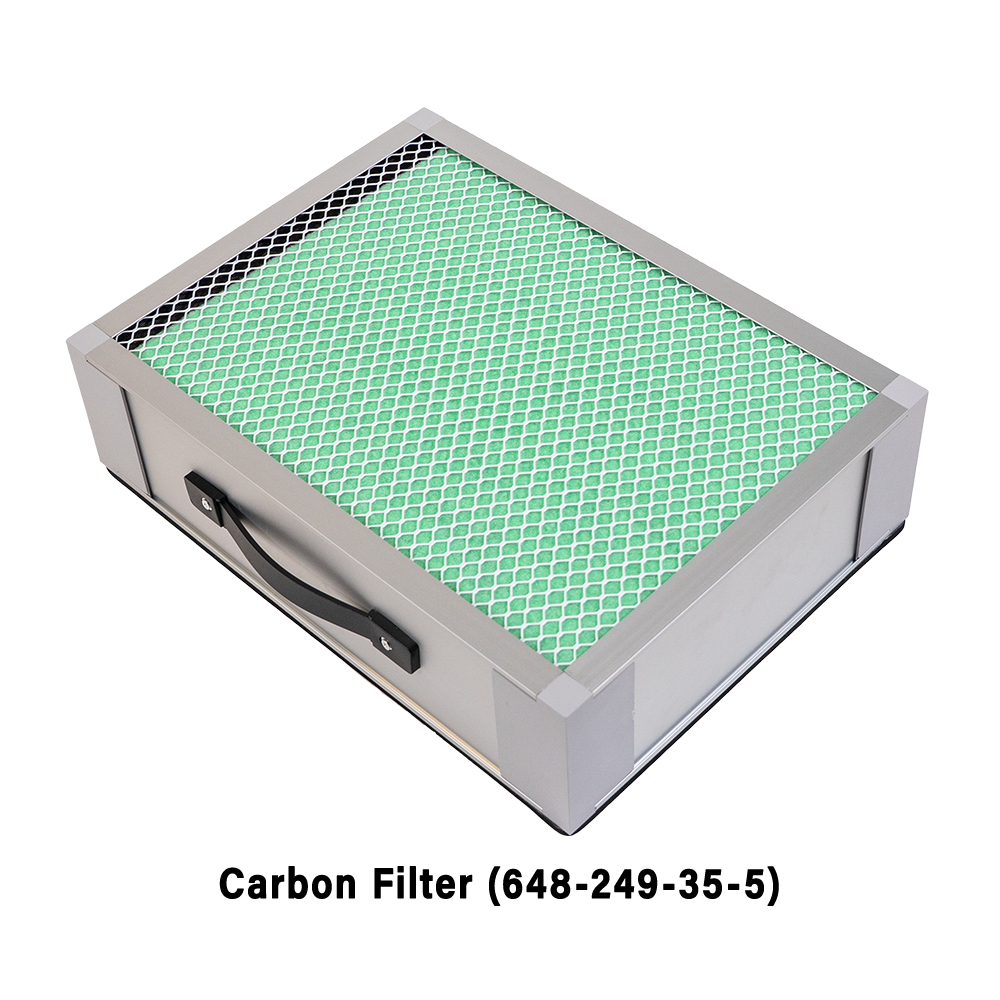

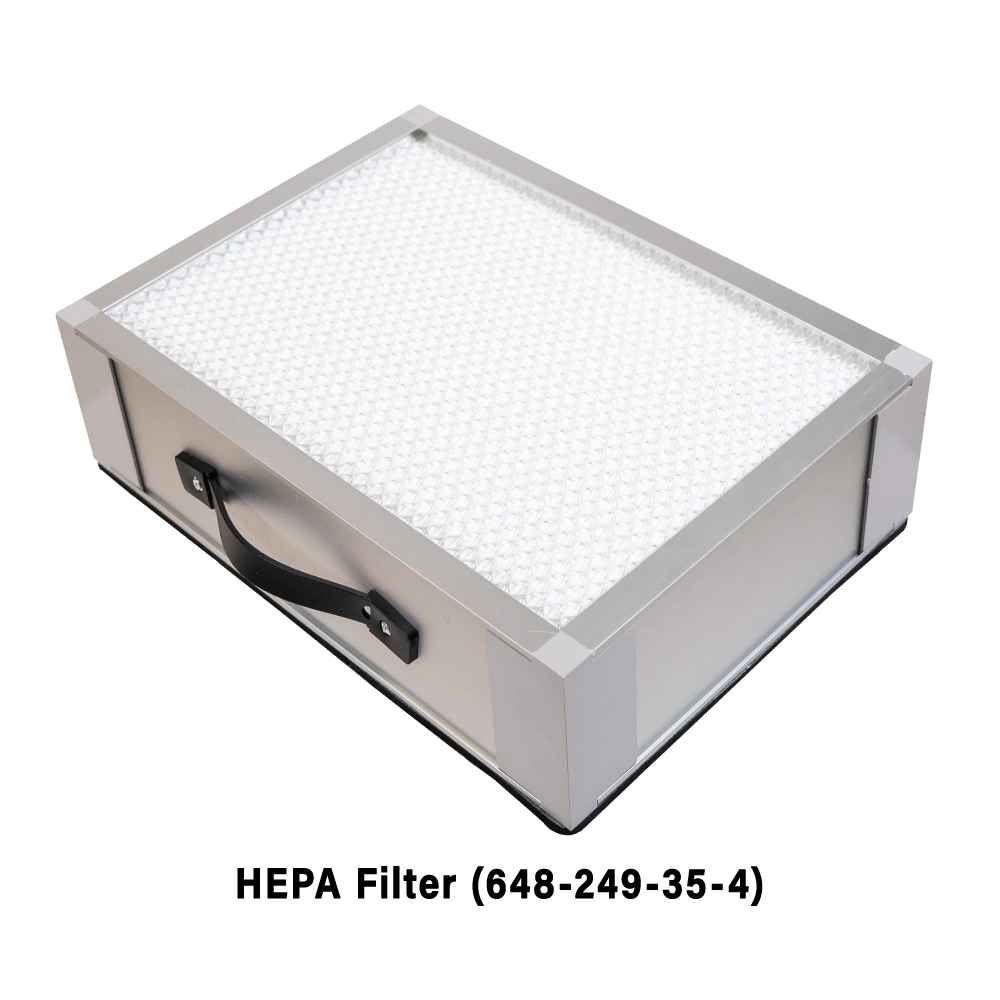

To protect both operator and equipment, the E350 incorporates a dual-filter configuration composed of:

-

A HEPA filter that captures 99.97% of fine particles, helping prevent dust from re-entering the environment and protecting optics and internal components. LaserStar Technologies

-

An odor carbon filter that absorbs fumes, volatile organic compounds (VOCs), and gases released during laser processing, contributing to safer exhaust air. LaserStar Technologies

Noise control is also a design priority. Despite its powerful fan, the system runs at a sound level of less than 53 dB, making it suitable in workshops or laboratories where noise can be a nuisance. LaserStar Technologies

Design, Build & Compatibility

The E350 Fume Extractor Vacuum Exhaust System is constructed with a compact yet robust form factor for long-term use. Its design supports both 120V and 230V supply circuits, making it suitable for multiple regional power configurations. LaserStar Technologies

Versatility is further enhanced by the included hose kit—either a 2-meter PVC hose or flexible hard plastic hose—allowing users to route extraction to different workstations or laser enclosures. The system also includes the capability for ON/OFF communication interface, enabling the fume extractor to synchronize with laser operation (i.e., turn on when lasing starts). LaserStar Technologies

Dual disposable bag filters capture larger debris and particulates, such as metal chips or slugs, including recovery of precious metals. These bag filters simplify maintenance and reduce load on the HEPA/carbon stages. LaserStar Technologies

Applications & Use Cases

Because the E350 Fume Extractor Vacuum Exhaust System combines heavy particle extraction and fine filtration, it is suitable across many laser-based operations:

-

Laser Welding: Extracting smoke and particulates from metal weld zones

-

Marking & Engraving: Managing fumes from ablation or removal of paint/coatings

-

Cutting & Cleaning: Capturing debris during laser cutting or laser cleaning operations

-

Precision Fabrication: Wherever airborne contamination must be controlled for optics or process quality

Beyond just fume extraction, using the E350 helps reduce particulate buildup inside laser enclosures, keep optics clean, capture cover gases, and maintain warranty compliance. LaserStar Technologies

Maintenance & Best Practices

To keep the E350 Fume Extractor Vacuum Exhaust System performing at peak:

-

Monitor airflow and suction—a drop can signal filter saturation or blockage

-

Replace HEPA and carbon filters periodically to maintain effective filtration

-

Change bag filters regularly to prevent clogging of downstream filters

-

Check hose integrity and connections to avoid leaks or backflow

-

Use synchronization so the unit runs only during laser operation, saving energy and prolonging filter life

By adhering to these practices, users can ensure cleaner air, extended system life, and more consistent performance from their laser environment.

Additional information

| Weight | 125 lbs |

|---|---|

| Dimensions | 10 × 20 × 9 in |

| Supply Circuit | 120V, 230V |