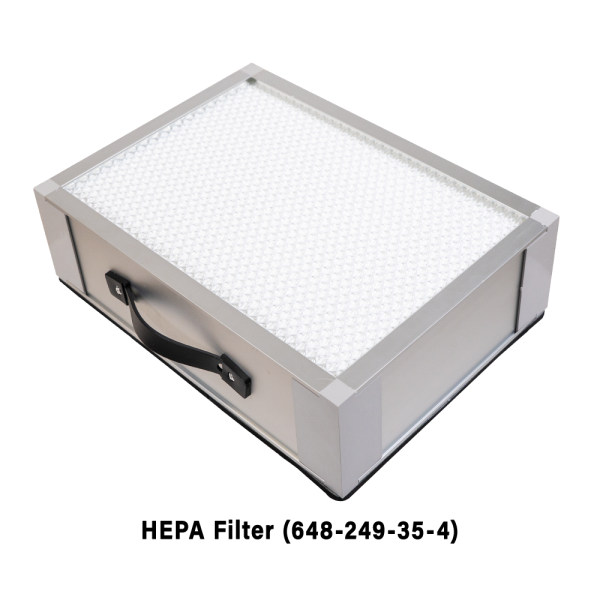

HEPA FILTER – E350 FUME EXTRACTOR

Part# 648-249-35-4

$85.00

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

Description

HEPA Filter E350 Fume Extractor

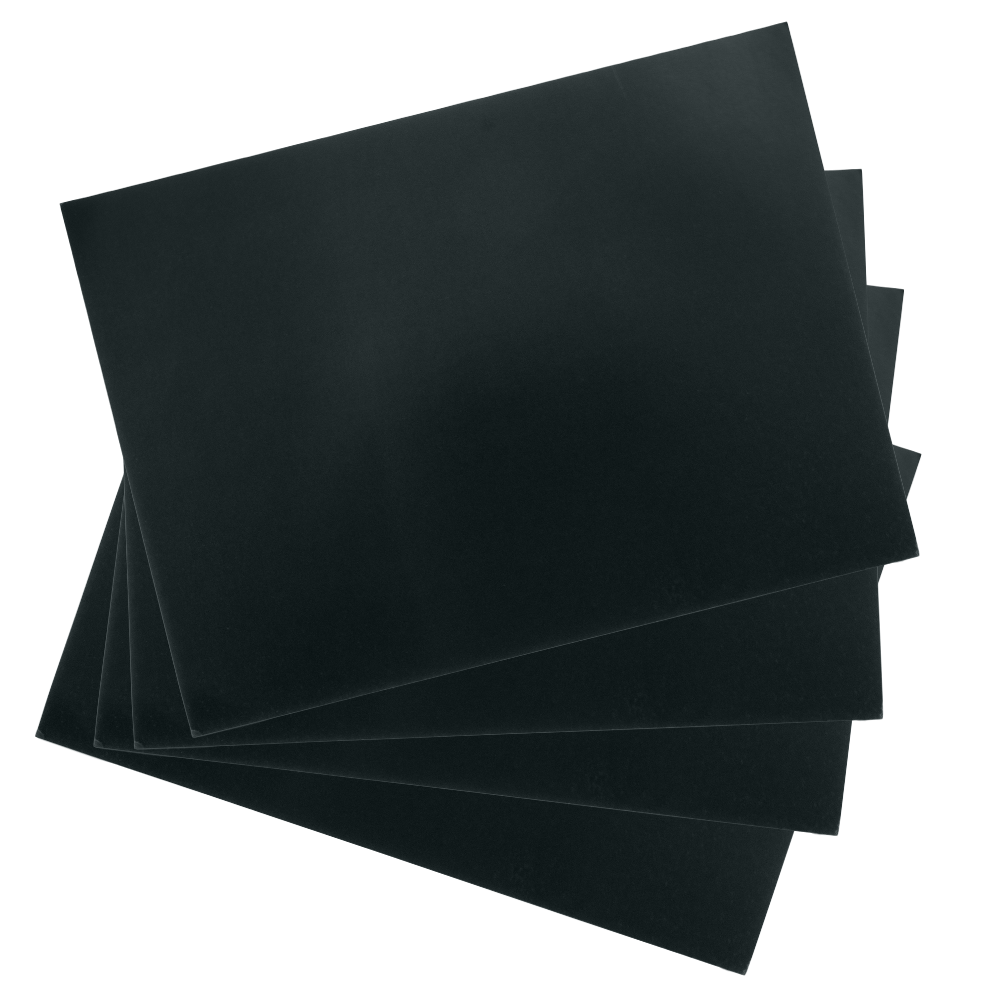

is a critical consumable component engineered to maintain optimal performance, air quality, and safety in laser fume extraction systems. The E350 fume extractor is designed to handle heavy particles, fumes, and particulates generated during laser welding, cutting, and engraving operations. To keep these systems functioning at peak efficiency, a high-quality HEPA filter is indispensable. This replacement filter is manufactured to meet the demanding standards required to trap microscopic particulates while supporting consistent airflow.

Importance and Functionality

In any laser industrial process, airborne particulates and fumes represent risks both to equipment (optics, enclosures) and to operator health. The HEPA Filter E350 Fume Extractor captures up to 99.97% of fine particles, effectively preventing them from being recirculated into the working environment. By installing a fresh HEPA filter, you ensure that your E350 system continues to trap ultrafine dust, smoke, and harmful byproducts from the welding process, maintaining clean air and protecting downstream components.

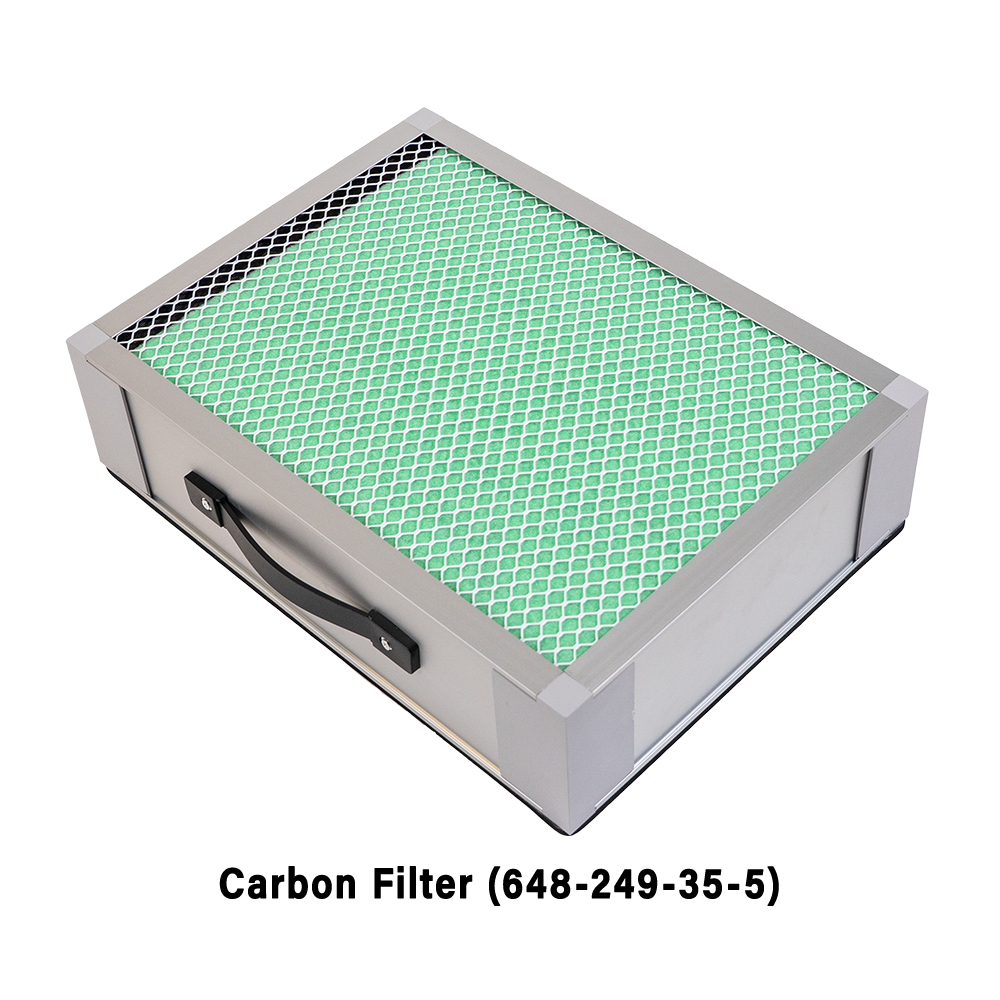

The E350 fume extractor unit is often outfitted with both a HEPA filter and a carbon/odor neutralizing filter. The HEPA stage captures the particulate matter, while the carbon filter handles gaseous components and odors. According to LaserStar’s product specifications, the E350 is engineered with both HEPA and odor filters to deliver comprehensive fume capture. LaserStar Technologies

Design and Compatibility

The HEPA Filter E350 Fume Extractor is built to align precisely with LaserStar’s E350 fume extraction systems. Its dimensions, sealing surfaces, and filter media are engineered to match the E350’s housing, ensuring an airtight, reliable fit. This compatibility ensures that you do not sacrifice filtration performance or airflow when replacing the filter. Because of its role in the system, this filter is considered a consumable—regular replacement is required to preserve system efficiency.

Performance and Benefits

A fresh HEPA Filter E350 Fume Extractor ensures your extraction unit continues to operate with minimal pressure drop, allowing the internal turbine or blower to maintain correct suction. Clogged or aged filters increase resistance, reducing airflow, increasing pump stress, and potentially reducing the life of the system. By replacing the HEPA filter timely, you can:

-

Maintain optimal airflow and suction power

-

Reduce particulate build-up inside the extractor and system enclosure

-

Protect sensitive optics and components from contamination

-

Enhance operator safety by reducing dusty or toxic fumes

-

Extend the life of the E350 fume extractor unit

Maintenance Guidance

To derive full value from the HEPA Filter E350 Fume Extractor, follow proper maintenance practices:

-

Monitor pressure or differential sensor indicators (if your E350 is equipped with them) to know when the filter needs replacing.

-

Replace the HEPA filter before it becomes clogged or reaches end-of-life, as indicated by usage hours or performance drop.

-

Handle replacement carefully to maintain the integrity of seals and filter media. Avoid dropping or crushing the filter.

-

Dispose of used filters properly, in accordance with local regulations, especially if they contain hazardous particulate.

-

If your system has pre-filters or collection bags, maintain them as necessary to reduce the load on the HEPA stage.

Application Contexts

The HEPA Filter E350 Fume Extractor is suited for use in settings where laser welding, cutting, or engraving generate particulate-laden exhaust. These include:

-

Industrial laser workshops and manufacturing plants

-

Medical device or electronics manufacturing

-

Jewelry and precision metalwork

-

R&D labs using micro-lasers or pulsed lasers

-

Repair stations or prototyping labs

In such environments, operators depend on clean, filtered airflow to prevent instrument damage, maintain cleanroom standards, and safeguard health.