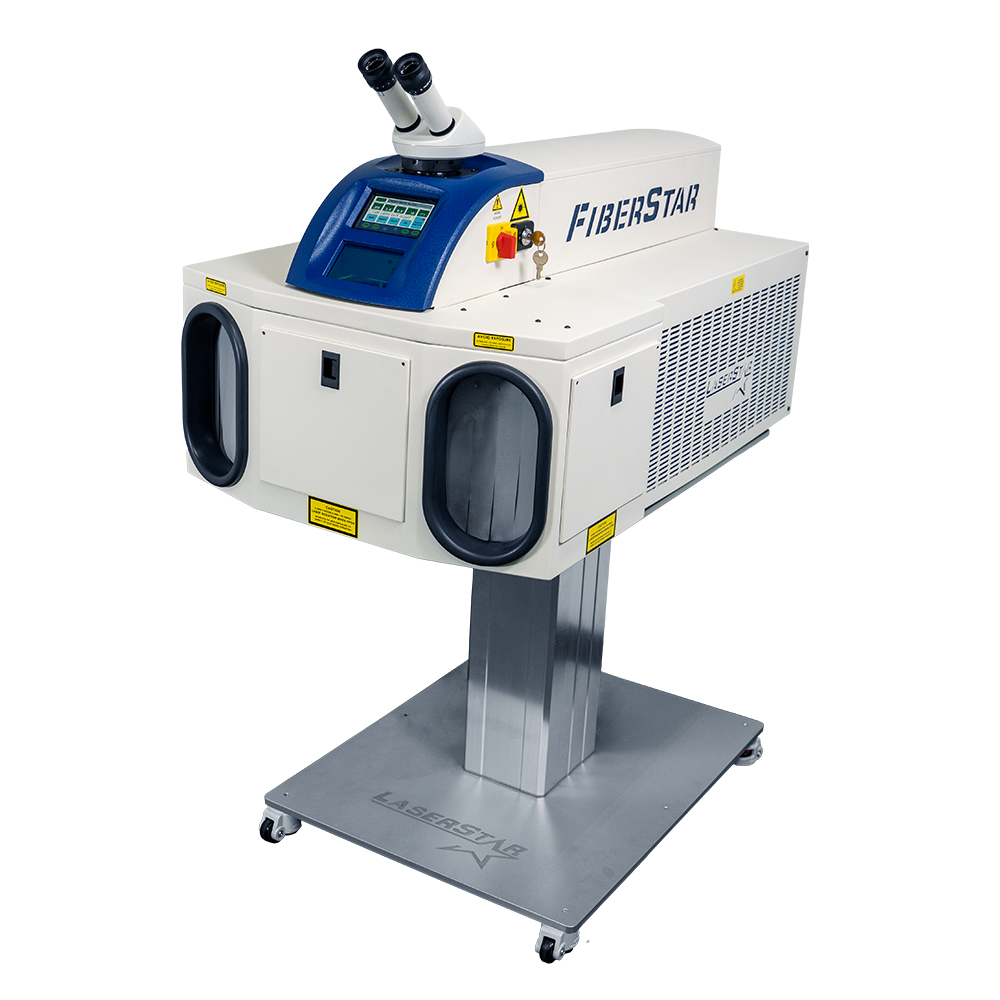

7601 FiberStar Industrial Laser Welder (150W or 300W)

Part# 524-761

CALL FOR QUOTE

The FiberStar Industrial Laser Welder (150W or 300W) utilizes advanced fiber laser welding technology with CW and pulse fiber engine output for high-precision welding. Featuring state-of-the-art laser resonator technology, this system delivers high peak power, optimal performance, enhanced efficiency, and a compact air-cooled design. With solid-state diodes, it provides instantaneous power with no warm-up time required.

Designed for long-term reliability and stability, the sealed laser source protects against dust and dirt, requires no consumable parts or adjustments, and ensures consistent material processing for years of operation.

Key Benefits:

✔ Minimal Heat Impact – Laser welds intricate parts with high precision and minimal thermal distortion

✔ Versatile Applications – Ideal for medical devices, aerospace, micro-welding, battery welding, mold repair, and electronics

✔ Fully Programmable Motion Packages – Supports single to four-axis programmable motion for maximum flexibility

Common Applications:

- Medical Device Welding

- Micro & Spot Welding

- Seam Welding & Battery Welding

- Mold Repair & Automotive Components

- Aerospace, Electronics & Computer Components

Contact LaserStar Technologies today to discuss your welding project, define application requirements, and receive a customized system solution tailored to your production needs.

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Technical Specs

- Product Brochure

- Additional information

- Laser Welding - Here is How it Works & More

Description

(Compatible with CW and Pulse Fiber Engine Output)

FiberStar Fiber Laser Welding Systems utilize cutting-edge laser resonator technology, delivering high peak power, superior performance, increased throughput, extended uptime, and enhanced electrical efficiency in a compact, air-cooled design. With solid-state diodes, these systems offer instantaneous power with no warm-up time required.

Designed for long-term reliability, the sealed laser source is resistant to dust and dirt, requires no consumable parts or adjustments, and is completely maintenance-free. This ensures consistent, high-precision material processing for years to come.

The FiberStar Fiber Laser Welding Workstation provides a competitive edge for industries with strict quality standards, including aerospace, medical devices, electronics, and micro-component assembly.

Key Advantages of Fiber Laser Welding:

✔ Produces a sharp, concentrated laser beam that precisely melts a small metal area

✔ Generates minimal heat at the weld point, allowing welding as close as >0.025mm from complex, heat-sensitive, or delicate parts

✔ Offers full parameter flexibility, supporting a 0-100% duty cycle

Applications:

- Medical Device Components

- Spot Welding & Seam Welding

- Mold Repair Welding & Micro Welding

- Battery Welding & Computer Components

- Aerospace & Electronics

- Automotive & Micro Components

Additional information

| Weight | 200 lbs |

|---|---|

| Dimensions | 37.5 × 15.8 × 44 in |