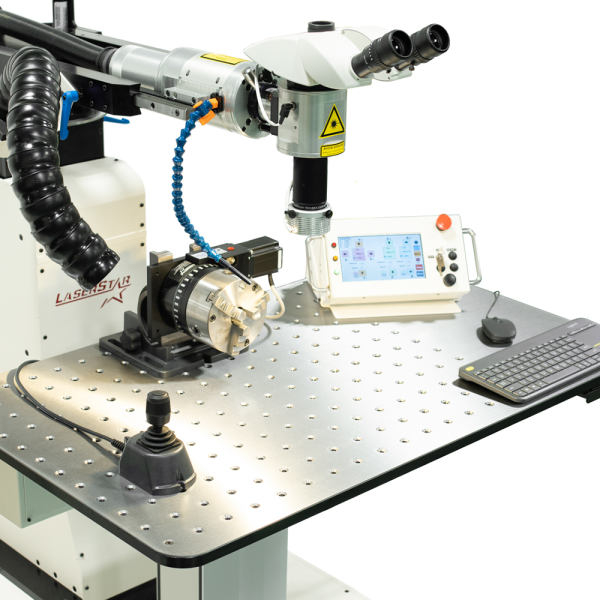

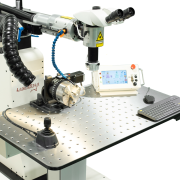

8900 FiberStar Industrial CNC Open Welding Workstation w/MotionFX® (150W – 600W)

8900 Series

Part# 514-890

CALL FOR QUOTE

The FiberStar 8900 Series CNC Welding Workstation delivers cutting-edge fiber laser technology for high-precision welding applications. Designed for industrial-grade performance, this system provides high peak power, optimal throughput, and enhanced electrical efficiency. The air-cooled, space-saving design ensures maximum uptime, while solid-state diodes deliver instantaneous power with no warm-up time required.

Key Applications of the FiberStar 8900 Series:

✔ Medical Device & Instrument Welding

✔ Aerospace & Automotive Component Fabrication

✔ Electronics & Micro-Welding Applications

✔ Battery & Energy Storage Solutions

✔ Industrial Tooling & Custom Metal Fabrication

✔ Jewelry & Precious Metal Welding

System Highlights:

✔ Advanced Fiber Laser Resonator Technology

✔ High Peak Power for Precision Welding

✔ Optimized Throughput for Increased Productivity

✔ Air-Cooled, Compact & Energy-Efficient Design

✔ Solid-State Diodes – No Warm-Up Time Required

✔ CNC Control for Automated Welding Processes

The FiberStar 8900 Series is built to handle high-precision, industrial welding applications, ensuring repeatable, high-quality results across a range of manufacturing environments.

Contact LaserStar Technologies today to discuss your welding project, define application requirements, and receive a customized system solution tailored to your production needs.

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Product Brochure

- Additional information

- Welding - How it Works & More

Description

Today’s mold repair micro-welding laser industry is characterized by rapidly changing, ever-evolving customer demands, and intense competition. Innovative ideas, successful designs, and a strong commitment to superior quality and performance are the fundamentals of LaserStar Technologies Corporation.

The laser source is a permanently sealed design that protects against dust and dirt, does not require adjustment, has no consumable parts, and requires no maintenance. These features help to ensure the FiberStar system’s performance resulting in stable, consistent material processing for years of operation.

Fiber laser welding technology produces a sharp, focused light beam that consistently melts a very small area of metal. The benefit of the technology is that very little heat is generated at the weld point allowing users to easily laser weld > 0.025mm from complex, heat-sensitive, intricate parts while providing unparalleled pulse stability of /- 1%.

Operators position or fixture the parts on the worktable while viewing the application through a stereo-microscope in the welding zone. An internal cross-hair allows the operator to easily align and weld the parts at the correct location.

The Fiber Laser CNC Welding Workstation offers a significant, competitive advantage for today’s operators looking to unleash the power of hot light, benefit from a comfortable, ergonomic design, and ensure optimal platform flexibility for the widest range of on-site mold repair welding applications.

FiberStar Fiber Laser Welding Systems are ideal for a wide range of complex alloys and applications including:

- Medical Device Components

- Spot Welding

- Seam Welding

- Micro Welding

- Mold Repair Welding

- Battery Welding

- Computer Components

- Aerospace and Electronics

- Automotive and Micro Components

Additional information

| Weight | 1140 lbs |

|---|---|

| Dimensions | 44.5 × 66 in |

| Wave Length | 1070nm |

| Warranty | As Quoted |

| Pulse Frequency | 0.5 – 20 Hz |

| Dimension | 50.5”L x 44.5”W x 66”H |

| Cooling | Internal Forced Air |

| Series | 8900 |