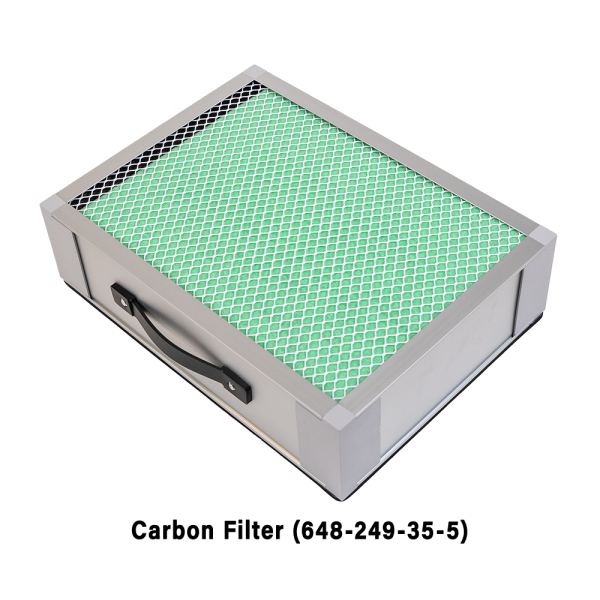

CARBON FILTER – E350 FUME EXTRACTOR

Part# 648-249-35-5

$90.00

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

Description

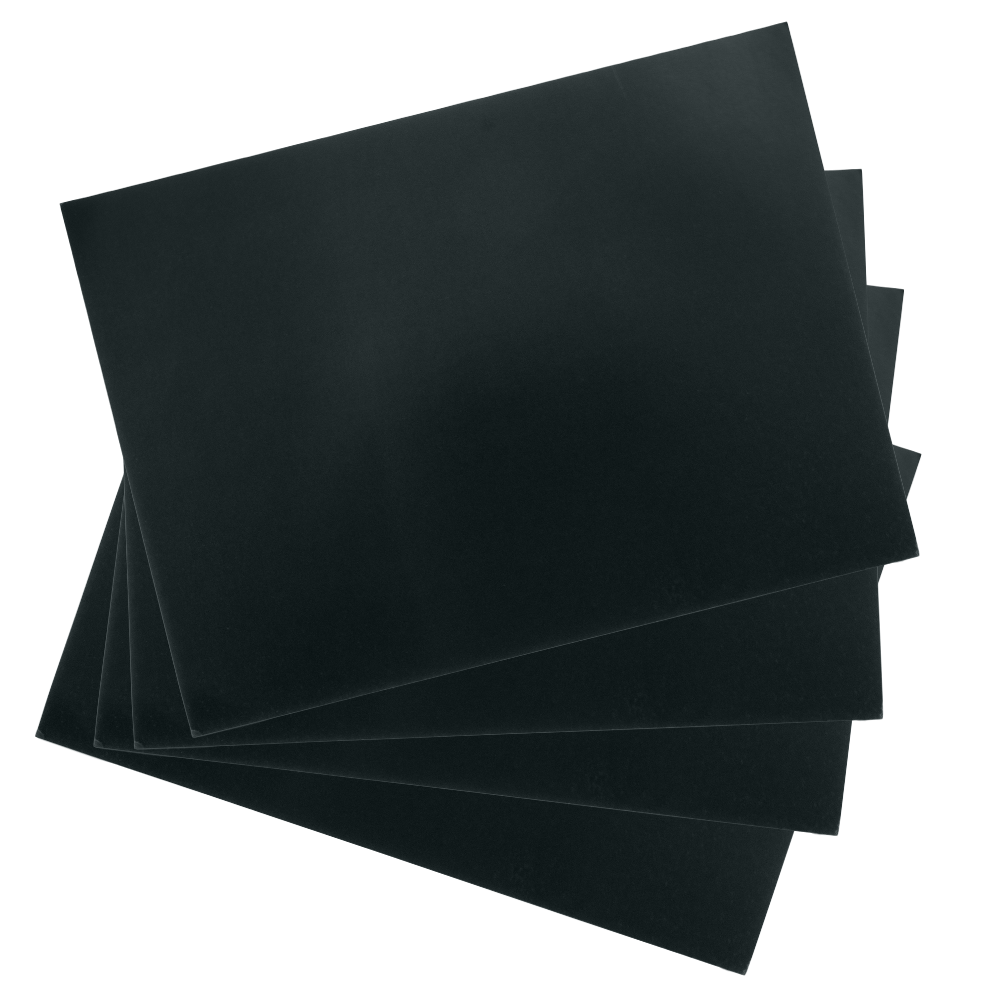

Carbon Filter E350 Fume Extractor

is a critical consumable component designed to enhance air quality and system performance when used with the LaserStar E350 fume extraction unit. When operating laser welding, cutting, engraving, or marking devices, fumes, vapors, and gases are generated; while particulate matter is handled by HEPA or collection filters, the carbon (or “activated carbon”) filter stage is responsible for capturing odorous gases, volatile organic compounds (VOCs), and chemical byproducts. By replacing or upgrading the carbon filter in your E350 system, you maintain cleaner air, reduce odor, and improve overall extraction effectiveness.

Why a Carbon Filter Matters

In many laser processing applications—such as metal coating removal, polymer ablation, or material engraving—volatile compounds are released. These gases may not be trapped effectively by particulate filters alone. The Carbon Filter E350 Fume Extractor works as an odor control and gas adsorption stage, absorbing these unwanted chemicals so that exhaust air becomes safer for the surrounding workspace. Without an effective carbon filter, fumes may pass through the system unmitigated, resulting in lingering smells or even potential hazards in enclosed environments.

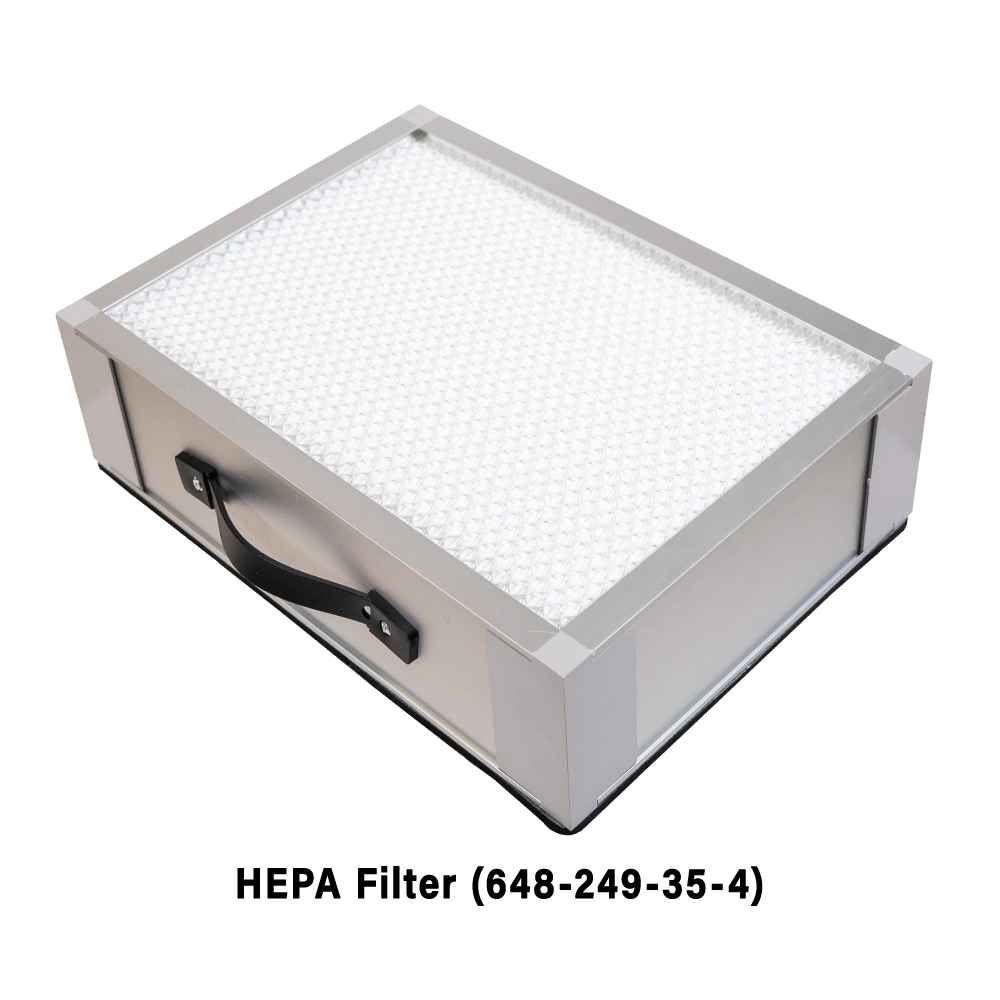

LaserStar’s E350 units are specified to include both HEPA filtration (99.97% of fine particles) and an ”odor carbon filter” to remove gaseous components. LaserStar Technologies+1 The carbon filter complements the particulate capture, making the overall extraction system more comprehensive and robust.

Compatibility & Design

The Carbon Filter E350 Fume Extractor is tailor-made for LaserStar E350 units. It fits perfectly into the designated filter housing, maintaining airtight seals and proper airflow characteristics to preserve the system’s suction efficiency. As a consumable, it’s designed to be user-replaceable, allowing maintenance personnel to swap filters without major downtime.

Because the E350 is engineered for continuous and demanding use—with brushless turbine motors, robust airflow (~430 m³/h), and integration in laser workstations—the carbon filter must meet stringent standards for adsorption capacity and airflow balance. DirectIndustry+1

Performance Benefits

Replacing or using a fresh Carbon Filter E350 Fume Extractor yields several important benefits:

-

Improved Air Quality & Odor Control: It absorbs volatile gases and fumes that the particulate filter cannot, helping maintain a safer, more comfortable workspace.

-

Maintained Suction Efficiency: When carbon filters become saturated or clogged, airflow resistance increases, putting stress on the intake blower or turbine. A clean carbon filter helps the system maintain optimal airflow and suction.

-

Extended System Life: By handling gaseous contaminants, the carbon stage protects downstream components (such as sensors, valves, or ducting) from chemical attack or contamination.

-

Regulatory Compliance & Safety: Many facilities require VOC and gas mitigation as part of environmental or occupational health standards. The carbon filter contributes to meeting those requirements when properly maintained.

Maintenance and Replacement Tips

To derive maximum benefit from your Carbon Filter E350 Fume Extractor, observe these best practices:

-

Scheduled Replacement: Monitor usage hours and performance indicators. Replace the carbon filter before it becomes fully saturated, especially in heavy-duty or high-gas-load environments.

-

Seal Integrity: Ensure that the filter housing gasket or seals are in good condition upon replacement to maintain an airtight fit.

-

Dispose Responsibly: Used carbon filters may contain adsorbed chemicals. Dispose of them in accordance with local hazardous waste regulations.

-

Combine with Pre-Filters: If your E350 system uses collection bags or prefilters, ensure those stages are clean to minimize load on the carbon stage.

-

Check Upstream Filters: If particulate filters are clogged or dirty, the carbon filter may be prematurely overloaded due to inefficient upstream capture.

Application Contexts

The Carbon Filter E350 Fume Extractor is suitable for use in environments where laser-based processes create fumes and gases, such as:

-

Laser welding of coated metals

-

Surface cleaning via laser ablation

-

Laser engraving or marking of plastics, polymers, or composites

-

Research labs processing materials with chemical coatings

-

Electronics manufacturing with solvent-based cleaning or resist removal