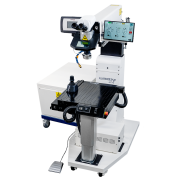

7803 LaserStar Industrial CNC Open Welding Workstation with MotionFX® (150W)

7803 Series

Part# 514-783

CALL FOR QUOTE

The LaserStar 783 CNC Open Welding Workstation is an advanced, joystick-controlled 3-axis laser welding system, featuring LaserStar’s MotionFX G-code programming software. Its open workspace design makes it ideal for a variety of applications, including plastic injection mold repair, die and tooling restoration, electronic component welding, high-precision industrial assemblies, and pressure-sensitive hermetic laser sealing.

With LaserStar’s cutting-edge laser technology, minimal heat is applied at the weld point, allowing for highly precise welding as close as <0.025mm to intricate, heat-sensitive components, while maintaining unmatched pulse stability.

Key Features:

✅ Portable Joystick Control for precision handling

✅ Robust Work Table with Z-Axis Adjustment (Supports up to 200 lbs / 91 kg)

✅ MotionFX® CNC X/Y/Z System for programmable welding

✅ Manual, Semi-Automatic & Full Automatic Modes

✅ Teach-Mode Enabled for ease of use

✅ Programmable Touch Screen Display

✅ Joystick with Fire Button Control Logic

✅ High-Accuracy X/Y/Z Axis Speed Control

✅ Optional Rotary Device for advanced applications

✅ Integrated Windows PC with MotionFX™ Software

✅ Telescoping Laser Rail Assembly for flexibility

✅ Tilting Optical Beam Path Head (Optional)

This item ships separately by freight and requires a custom shipping charge. This policy does not apply to spare parts & accessories under 10lbs/4.5kg.

- Description

- Technical Specs

- Product Brochure

- Laser Welding - Here is How it Works

- Additional information

- Soft-Touch™ Resonator Technology

- Pulse Performance Profile Technology®

- Common Weldable Alloys

Description

The LaserStar 783 CNC Open Welding Workstation is a cutting-edge, joystick-controlled, three-axis laser welding system featuring LaserStar’s advanced MotionFX® G-code programming software. Designed with an open workspace, this versatile system is ideal for a variety of precision welding and component assembly applications, including plastic injection mold repair, die and tooling restoration, complex electronic components, high-precision industrial assemblies, and pressure-sensitive hermetic laser sealing.

One of the key advantages of LaserStar’s laser welding technology is its ability to generate minimal heat at the weld point, allowing users to weld as close as 0.025mm to intricate, heat-sensitive components while ensuring exceptional pulse stability.

Key Features:

✔ Portable Joystick Control

✔ Robust Work Table with Z-Axis Adjustment (Supports up to 200 lbs / 91 kg)

✔ MotionFX® CNC X/Y/Z Integrated System

✔ Manual, Semi-Automatic, and Fully Automated Operation Modes

✔ Teach-Mode Enabled for Precise Programming

✔ Programmable Touchscreen Display

✔ Joystick with Fire Button Control Logic

✔ High-Precision X/Y/Z Axis Speed Control

✔ Optional Rotary Device for Enhanced Functionality

✔ Integrated Windows PC with MotionFX™ Software

✔ Telescoping Laser Rail Assembly

✔ Optional Tilting Optical Beam Path Head

With its state-of-the-art technology and user-friendly controls, the LaserStar 783 CNC Open Welding Workstation delivers superior precision, efficiency, and reliability for industrial laser welding applications.

| Laser Source | Nd:YAG (1064nm) |

| Operator Pulse Energy | 0,1 – 150 Joules |

| Average Output & Peak Power | 150W (10kW) |

| Pulse Frequency | 0.5 – 20 Hz |

| Beam Diameter | 0,5 – 2,00mm |

| X-Y Axis, Table Lift Column Travel | 250mm x 250mm x 200mm |

| Max Load | 200 lbs (91 kg) |

| XY Resolution (μm) | 12.5 microns |

| Accuracy (Linear Axis Only) | +/- (25 microns) per 25mm of travel |

| Speed (mm/sec) | 15mm/sec |

| Software | CNC MotionFX® w/ Teach-Mode & Manual |

| Joystick | Direct Axis Control, Fire Button |

| Cooling Capacity | Internal Forced Air / 24 hr Continuous Run Time |

| Shielding Gas/Compress Air | Dual – Integrated “Soft Flow” Nozzle |

| Weight | Approx. 260 lbs./118KG |

| Supply Circuit | 208-240 V, 50/60Hz, Single Phase |

| Laser Safety Compliance | FDA (CDRH), CSA, CE |

Additional information

| Series | 7803 |

|---|