Laser Welding Jewelry: Why Every Jewelry Store Should Own a Laser Welder

What I’ve seen over the years is that a laser welder is frequently one of the top two or three items on a jeweler’s wish list. So if I owned a jewelry store, I’d make sure I had one, because it offers benefits every jeweler can take advantage of.

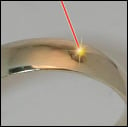

A laser welder allows you to create a new profit center for generating revenue, by way of custom manufacturing and providing fast and timely jewelry repairs. As a tool, it has revolutionized the bench jeweler’s skill set. My sense is that in today’s economy, many retailers aren’t getting the volume they used to selling goods straight out of the showcase. A laser welder offers a chance to reinvent their business model to accommodate custom jewelry design: You can pick out findings and select different stones, source all those components, and then rapidly assemble a finished, high-quality piece without soldering.

It’s also easier to learn. You can learn to use a laser in eight to 12 hours — just come to a LaserStar two-day laser welding training course, and we can teach you to make money with it immediately. And after another 20 hours, you’ll be very proficient at laser welding. Conversely, teaching somebody to use a torch is a fairly intensive process and there’s not a lot of room for error.

Because of that, it has also become important to have a laser welder if you want to hire fresh talent on the bench and remain competitive. Apprenticeship opportunities are rapidly deteriorating; it’s not like the old-world approach anymore, where a master would hire an apprentice who would train for five years under him. All the colleges have laser welders, so students are coming out, looking for jobs, and saying to jewelers, “Where’s your laser welder?” Our curriculum is actually used at GIA (Gemological Instutute of America).

“I just got back from laser training with LaserStar Technologies, and I have to tell everyone, if you have a laser and didn’t take the course, you are missing the boat and swimming upstream.“ – Reagan Steele Jewelers, Sayre, PA

Finally, if I wanted to get really creative, I could go out and market my laser-welding services to, say, eye doctors. I’d tell them when people came in with broken eyeglasss frames to send them my way — a laser welder is perfect for repairing that kind of thing. It’s a tremendous tool in plenty of other industries, too: tool and die manufacturers, medical device manufacturers, prototyping work. If I were looking for additional revenue, I could contact people in those fields and say I was more than happy to rent them the use of the laser welder as a tool for $50 an hour during my off-hours.

James Gervais is president and chief operating officer of LaserStar Technologies.

{{cta(‘4f203111-b7c5-4b26-a2ca-8495ccb9e9a9′,’justifycenter’)}}