Laser Welding

admin2025-03-01T13:46:58-05:00LASER SPOT & SEAM WELDING TOOLS

Industrial Laser Welding Systems

Industrial laser welding has had a dramatic impact in the Machine Tool Industry over the years, and has become the answer to many problems brought about by traditional welding methods. Many metalworking companies have turned to laser spot and laser seam welding due to these advantages. Automation, high welding speeds and contact-free processing help laser welding users achieve economic advantages very quickly.

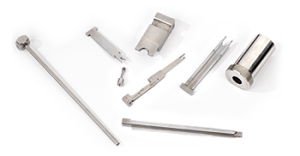

Since laser welding produces pure, concentrated energy, it creates deeper welds while leaving high production output. This is one of the many reasons laser spot and seam welding systems are used in manufacturing in this industry. Items we use every day in our gadgets, electronics and parts have gone through laser welding technology in the course of their production.

Laser Spot Welding & Laser Seam Welding

Laser spot welding, laser seam welding, and direct welding are highly useful and slightly differing applications of laser welding technology. Laser spot and seam welding refers to welding functions applied to a single point or along a line. By setting a laser welding system to a high speed and extremely narrow weld geometry, the laser welder can produce extremely fine spot welding. Also, you can adjust the system to weld on continuous wave mode, welding with several kilowatts of power. The ideal laser speed for laser spot or seam welding projects varies according to the particular laser model, the laser power setting, and the material being laser welded.

Contact LaserStar to discover the ideal laser welding system for your needs.