LASER WELDING ORTHODONTICS

admin2024-05-16T17:39:42-04:00LASER WELDING ORTHODONTICS

Tips for Laser Welding Orthodontics

Tips for Laser Welding Stainless Steel

The LaserStar laser welding system is an excellent tool for assembling most fixed and removable orthodontic appliances. Stainless Steel laser welds best by using the following parameter combinations:

215 – 225 V 1.0 – 3.0 MS 2.0 – 3.0 HZ .45 – .55 Ø WITH BASIC PULSE PROFILE

Use of Argon gas is highly recommended when laser welding Stainless Steel. Improper argon flow will result in oxidizing of the metal.

Tips for Laser Welding Thin Stainless Steel

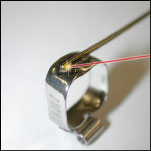

When welding thin Stainless Steel parts such as a Band to a Bar, be sure to use a lower Voltage, higher Millisecond with the BURST PROFILE SETTING. The use of BURST profile will prevent the laser welder from bursting holes in the thinner band. The following Parameter combinations were performed on an 80J iWeld Laser Welding System.

NOTE: Parameters may vary depending on the Joule energy output of the laser, flash-lamp age, and alloy surface condition.

185 V 9.0 MS 3.5 HZ .55 Ø WITH BURST PULSE PROFILE

It is also necessary to fire the laser welder at an angle of about 30° to 45° to the seam. Firing the laser at too steep of an angle to the band can result in a hole in the band.

Incorrect Angle

Correct Angle

When laser welding any thick to thin material, it is necessary to favor the thick material. For instance, in the case of welding a bar to a band, aim the cross hair slightly on the bar. The bulk of the laser energy will be absorbed by the thicker material (the bar). If the parameters are correct, the heat transfer will laser weld the band to the bar without bursting a hole in the band.