DENTAL LAB LASER WELDING: PARTIAL DENTURES

admin2024-05-16T17:12:21-04:00DENTAL LAB LASER WELDING: PARTIAL DENTURES

Tips for Extending a Rest with Laser Welding - Partial Dentures

In the event that a rest does not cast out properly, or an existing rest is worn thin, the LaserStar can be used to extend or build-up the rest.

Filling:

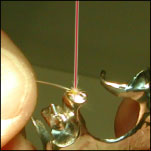

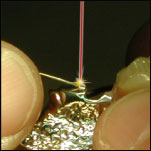

Hold LaserStar welding wire of the same alloy at a 30° angle or less, making sure the tip of the filler wire touches the base metal (the area you wish to extend or build). Fire the LaserStar at a 90° angle until the metal “puddles” onto the rest.

TIP: It is OK to add a little extra metal onto the rest. You may remove any excess metal by grinding to fit to the model.

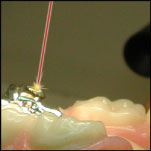

Hammering and Smoothing

It is now necessary to increase the Beam Diameter (Ø) This will reduce the depth of the weld resulting in a Surface Weld. Also, increase the Hertz (HZ). This will enable the LaserStar to fire more rapidly, keeping the metal molten for ease of smoothing. Fire the LaserStar moving the item slightly in a back and forth motion. This will “feather” the metal across the fill zone resulting in a smooth hammering effect.

Clean Up

Clean up the area by grinding, sanding, or using a rubber wheel. Then clean or sandblast accordingly.

Examples of Extended Rests after grinding are shown above.